How to Minimize Dimensional Weight Fees with Void Fill

Shipping costs can skyrocket when carriers charge based on dimensional (DIM) weight instead of actual weight. DIM weight pricing factors in package size, penalizing excess space and void fill. To reduce fees:

- Choose the smallest box that fits your item safely.

- Use lightweight void fill like air pillows or bubble wrap strategically.

- Measure dimensions accurately, as carriers round up to the nearest inch.

- Calculate DIM weight: Multiply length × width × height, divide by the carrier's DIM divisor (e.g., 139 for FedEx, 166 for USPS retail).

- Test for excess void fill by checking if the item rattles or needs excessive filler.

For high-volume shippers, tools like Navexa's box optimization system or custom box makers can help cut costs by matching box sizes to products and reducing void fill. Negotiating higher DIM divisors with carriers or bundling orders can also lead to significant savings.

Top 10 Ways To Improve Dim Weight Shipping Process

sbb-itb-ed0a9d1

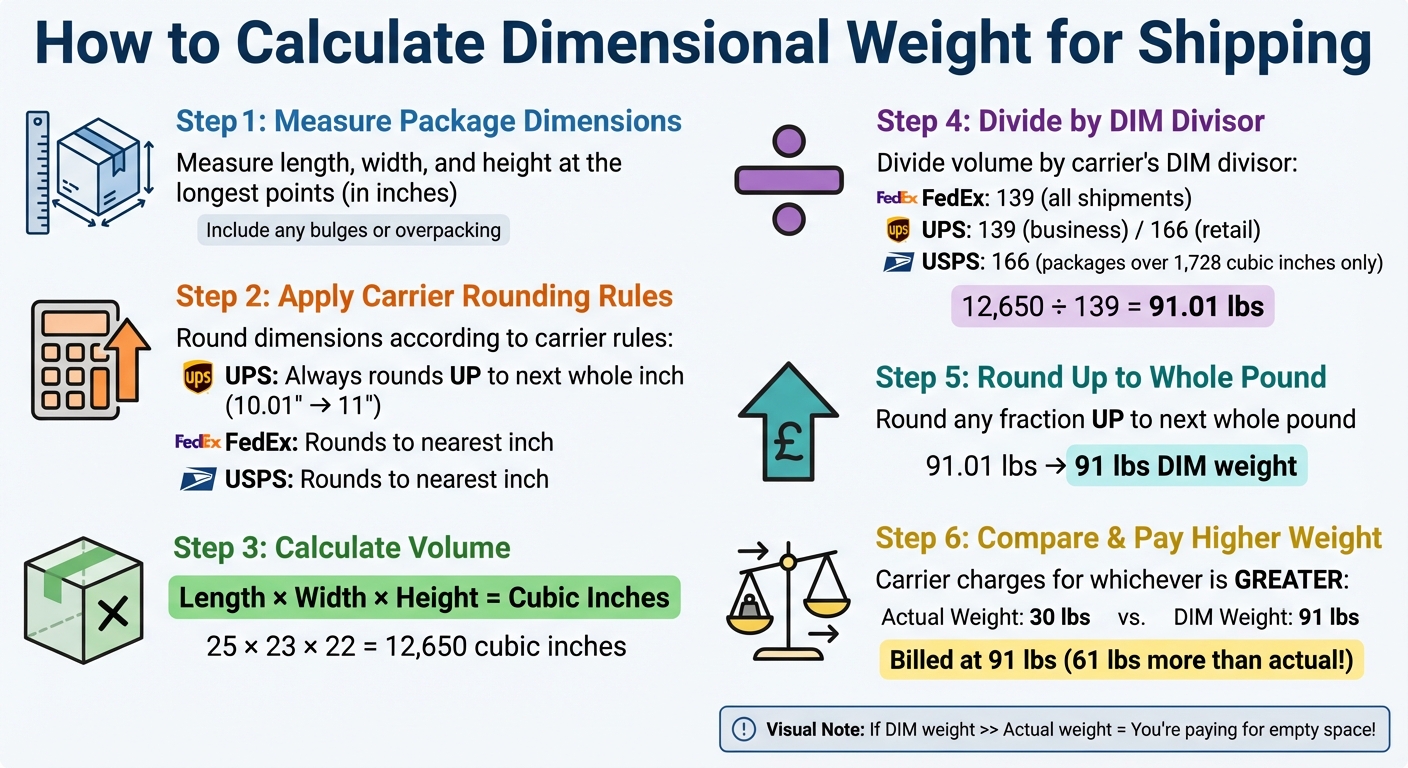

How to Calculate Dimensional Weight

How to Calculate Dimensional Weight for Shipping: Step-by-Step Guide

Accurate DIM weight calculation is essential when it comes to managing shipping costs. While the process isn’t overly complex, precision is key. Start by measuring the package at its longest points - length, width, and height - using inches. Make sure to account for any bulges or overpacking, as carriers measure the outermost dimensions, and even minor excess can increase your chargeable size.

Once you have the measurements, apply the rounding rules of your carrier, as these vary. For example, UPS always rounds up to the next whole inch (e.g., 10.01 inches becomes 11 inches), while FedEx and USPS round to the nearest inch. These small adjustments can make a big difference - rounding up by even half an inch on all three dimensions might push you into a higher billing tier.

Next, multiply the rounded dimensions to calculate the package’s volume in cubic inches. Then, divide this number by the DIM divisor used by your carrier. For reference:

- FedEx uses a divisor of 139 for all shipments.

- UPS uses 139 for daily business rates and 166 for retail rates.

- USPS uses 166 but only applies DIM pricing to packages larger than 1,728 cubic inches (equivalent to 1 cubic foot).

The resulting number is your dimensional weight in pounds. Always round up any fraction to the next whole pound, as carriers bill based on whole numbers.

Step-by-Step Calculation Process

Here’s an example: let’s say you have a box that measures 25 x 23 x 22 inches and weighs 30 lbs. First, calculate the volume:

- Volume: 25 x 23 x 22 = 12,650 cubic inches.

Now, divide the volume by the carrier’s DIM divisor. Using UPS’s divisor of 139:

- DIM Weight: 12,650 ÷ 139 = 91.01 lbs.

Round up to the nearest pound, and the DIM weight becomes 91 lbs. Since carriers charge for the greater of the actual weight or DIM weight, you’d be billed for 91 lbs - 61 lbs more than the actual weight. This example illustrates how excessive void fill can significantly inflate shipping costs.

For USPS, first check if your package exceeds 1,728 cubic inches. If it doesn’t, you’ll be charged based on the actual weight. For non-rectangular packages, USPS applies an adjustment factor of 0.785 to the cubic volume before dividing by 166.

Testing for Excess Void Fill

If your DIM weight is much higher than the actual weight, it’s a sign you’re paying for empty space. A quick way to check: does your product rattle around inside the box, or does it need a lot of filler to stay secure? If so, the box is likely too large. Always measure the package after packing, as void fill and contents can cause dimensions to exceed the box’s printed size.

"Void space is the silent cost driver in shipping. The more air in your box, the more you're charged." - Marilyn Bunderson

To minimize void fill, try arranging items snugly, like fitting pieces in a game of Tetris. This reduces internal gaps and the need for filler material. By following these steps, you can refine your packing approach and cut down on unnecessary shipping expenses. For more optimization tips, explore our shipping resources and guides.

Choosing the Right Void Fill Materials

Once you've identified excess void space through testing, the next step is picking the right void fill material. The goal? Protect your products while keeping dimensional weight (DIM) fees in check. Your choice should balance product fragility and the amount of fill required. For example, air pillows are great for filling large gaps without adding much weight, making them an excellent choice for high-volume shipping where the DIM weight already surpasses the actual weight.

For fragile items, bubble wrap and foam rolls provide excellent shock absorption with minimal added weight - especially after optimizing your box size. Kraft paper is a cost-effective option for blocking heavier items, though it adds moderate weight. If you're dealing with irregularly shaped products, packing peanuts conform well to odd spaces while keeping weight low.

"Think of void fill as your item's bodyguard for shipping; it's what makes certain that each product gets delivered just how you packed it - intact and undamaged." - The Boxery Team

Another option is honeycomb inserts, which offer strong structural support while allowing for smaller box sizes. Though they tend to cost more per unit than paper or peanuts, they can help reduce DIM weight significantly.

Types of Void Fill Materials

Here’s a closer look at some common void fill materials and their characteristics:

- Air pillows: These are perfect for filling large empty spaces without adding much weight. While they require an upfront investment in an inflation machine, they’re lightweight and cost-efficient for high-volume shipping.

- Bubble wrap: Ideal for fragile or oddly shaped items, bubble wrap holds its structure well but can be punctured during rough handling.

- Kraft paper: Best for heavier items that need to stay in place. Its protective quality depends on its basis weight; for instance, a higher basis weight like 60# offers stiffer, more protective paper.

- Anti-static foam rolls: Often used for electronics, these foam rolls (usually pink) help dissipate electrostatic charges during transit.

- Packing peanuts: Available in traditional polystyrene or biodegradable versions, peanuts are great for filling gaps around irregularly shaped objects. Biodegradable options dissolve in water, offering a more eco-friendly alternative without sacrificing protection.

- Honeycomb inserts: These create air pockets similar to bubble wrap but are made from paper, making them recyclable and environmentally friendly. They also maintain strong structural integrity.

Both air pillows and Kraft paper stand out for their ability to save storage space compared to bulkier materials like bubble wrap or prepackaged peanuts.

Material Comparison Table

| Material | Weight Added | Cost | Protection Level | Impact on DIM Weight | Best Use Case |

|---|---|---|---|---|---|

| Air Pillows | Negligible | Moderate* | High | Minimal | Filling large empty spaces in oversized boxes |

| Bubble Wrap | Low | Moderate | High | Low | Wrapping fragile or oddly shaped items |

| Kraft Paper | Moderate | Low | Moderate | Moderate | Blocking/bracing heavier items |

| Packing Peanuts | Low | Moderate | Moderate | Low | Filling gaps around irregular objects |

| Foam Rolls | Low | Moderate | High | Low | Surface protection for electronics |

| Honeycomb | Low | Moderate to High | High | Low | Structural support with an eco-friendly profile |

*Requires inflation machine investment

When deciding on void fill, start by choosing the right box size to limit empty space. Then, pick a material that aligns with your product's fragility and shipping needs. A simple shake test - gently shaking the packed box - can help you determine if items are secure. If you hear movement, it’s a sign that more filler is needed. As a general rule, aim for at least two inches of padding on all sides of the item to ensure it stays protected during transit.

Best Practices for Reducing Dimensional Weight Fees

Optimize Box Sizing and Positioning

One of the simplest ways to lower DIM weight fees is to choose a box size that closely matches your product's dimensions. Shipping oversized boxes means you're essentially paying to transport air. By arranging items snugly, you can create a compact package that minimizes wasted space.

Keep a variety of box sizes in your inventory to accommodate different products. For items that don’t fit standard boxes, consider disassembling them into smaller parts. This way, you can use more compact, standard-shaped boxes instead of larger, irregular ones. When packing multiple items together, stack or nest them efficiently to maximize density. Use void fill strategically - aim for at least two inches of padding on all sides to protect your items, but avoid over-padding, as it can unnecessarily increase the box's size. Finally, make sure to measure your package dimensions accurately to avoid inflated fees.

Avoid Rounding Up Dimensions

Precise measurements are just as important as using the right box. Carriers typically round up dimensions to the nearest whole inch, which can push your package into a higher weight bracket. For instance, a box measuring 12.1 inches will be billed as 13 inches. This seemingly small difference can lead to higher shipping costs.

To avoid this, measure each side of your package at its longest point, including any bulges, and choose boxes that keep the final dimensions just below the next whole inch. For example, if your packed item measures 11.8 inches, select a box that ensures the final measurement stays under 12 inches. This attention to detail can save you from unexpected charges.

Use Navexa's Box Optimization Tool

Taking these steps manually can be time-consuming, but tools like Navexa's box optimization system make the process much easier. This automated tool eliminates guesswork by using advanced dimensioning technology to determine the ideal box size for every order. With real-time processing that captures dimensions, weight, and images in as little as 0.2 seconds, and with a precision of 0.2 inches, it ensures accuracy every time.

Navexa's algorithms analyze your product specifications and automatically select the most efficient box, reducing the need for void fill by 10–15%. Additionally, its multi-carrier rate shopping feature compares shipping rates across carriers, ensuring you always get the best deal based on your package's dimensions and weight. With seamless integration across more than 50 e-commerce platforms, Navexa allows you to implement automated box optimization without disrupting your workflow.

Advanced Techniques for Reducing Dimensional Weight Costs

Once you've mastered the basics, there are advanced strategies that can help cut dimensional (DIM) weight costs even further.

On-Demand Box Makers for Custom Fits

On-demand box-making technology takes packaging to the next level by creating custom cartons in real time. These systems use AI and automated cutting tools to produce boxes that match the exact dimensions of each order. This eliminates the need to rely on standard-sized boxes, which often result in wasted space - and wasted money. By reducing shipping volume by up to 40%, this approach ensures you're not paying to ship empty air.

For example, using a custom 10″ x 8″ x 6″ box (DIM weight ~3.5 lbs) instead of a standard 12″ x 12″ x 8″ box (DIM weight ~8.3 lbs) can save approximately $3.84 per shipment at a rate of $0.80 per pound. These systems also streamline operations by pulling item dimensions directly from your product database, eliminating the inefficiencies of manual packing. A review of your box inventory might reveal that 80% of shipments rely on just 20% of your available box sizes. When combined with strategies like rate shopping and order bundling, custom box solutions can unlock even greater savings.

Using Navexa's Multi-Carrier Rate Shopping

Shipping costs can vary widely depending on the carrier, as different companies use unique DIM divisors and rounding rules. Navexa's multi-carrier rate shopping tool compares rates across carriers in real time, helping you select the most cost-effective option for each shipment.

For instance, FedEx and UPS typically use a divisor of 139 for domestic shipments, while USPS Priority Mail uses 166. A higher divisor translates to lower billable weight, reducing costs. Additionally, carriers like FedEx and UPS round up fractional inches, which can increase billable weight by as much as 20%.

"Even a ¼" can cause packages to get billed at higher weights than expected."

– Sean Kim, VP of Parcel, Kase

Navexa's platform takes these carrier-specific rules into account, including thresholds for Additional Handling surcharges and minimum billable weights. For example, FedEx enforces a 40-lb minimum for certain shipments. By factoring in these variables, Navexa ensures you're always choosing the most cost-effective carrier for your package dimensions.

In addition to optimizing box sizes and carrier selection, bundling orders can further drive down shipping expenses.

Bundle Orders and Negotiate DIM Divisors

Bundling multiple items into a single shipment can slash shipping costs by up to 30%. Instead of paying separate base rates and DIM weight charges for multiple packages, consolidating items into one box can save anywhere from $10 to $25 per order.

For businesses shipping at high volumes (10,000+ packages per month), negotiating a higher DIM divisor can lead to substantial savings. For instance, switching from a divisor of 139 to 166 can significantly lower billable weight. A package measuring 5,832 cubic inches would drop from 42 lbs to 35 lbs, cutting its billable weight by 16.6%.

"DIM factor adjustments are perhaps one area that is not actively negotiated with carriers by many businesses... We've seen clients able to get a 166 DIM divisor instead of 139, which saves them thousands in shipments for high volumes."

– Robert Khachatryan, CEO and Founder, Freight Right Global Logistics

Surprisingly, only one-third of shippers negotiate custom rates, leaving a lot of potential savings on the table. Before entering negotiations, analyze a year's worth of shipping data to identify where dimensional weight penalties are driving up costs. When it’s time to renew contracts, be sure to request adjustments to your DIM divisor and leverage your shipping volume to strengthen your position. If your shipping volume isn’t high enough to negotiate directly, consider partnering with a third-party logistics provider (3PL). Many 3PLs offer access to pre-negotiated contracts with more favorable DIM divisors.

Conclusion

Shipping costs can quickly spiral out of control when dimension-based fees come into play, but smart packaging choices and efficient void fill can help keep expenses in check. Since carriers charge based on the higher of actual weight or dimensional (DIM) weight, every extra inch of packaging adds to your costs. This makes it essential to streamline your packaging strategy.

Start by accurately calculating DIM weight using the formula (L × W × H) ÷ Divisor to avoid surprise charges. Choose void fill materials that protect your products without unnecessarily increasing package size. Additionally, regularly review and adjust your box inventory to eliminate wasted space and reduce reliance on excess void fill.

For businesses handling large shipping volumes, these savings can add up fast. Tools like Navexa’s box optimization and multi-carrier rate shopping simplify the process by automating box selection and carrier choice. By adopting these strategies and leveraging automation, you can consistently cut shipping costs while maintaining efficiency.

FAQs

What’s the best way to choose the right box size to reduce dimensional weight fees?

To cut down on dimensional weight (DIM weight) fees, the first step is to measure your item precisely, including any unusual shapes or protrusions. Then, choose a box that fits your item snugly, leaving little to no extra space. Oversized boxes can unnecessarily increase the package's volume, which directly impacts DIM weight calculations.

DIM weight is determined by carriers using this formula: package volume (length × width × height) divided by their specific dimensional divisor, often 139 or 166. Picking a box that’s just the right size and avoiding excess void space helps keep the DIM weight as low as possible, which can significantly lower your shipping expenses.

For protecting your items without adding unnecessary bulk, lightweight materials like packing paper or air pillows are great options. They provide cushioning while keeping the package size in check.

What are the best void fill materials to lower shipping costs?

When it comes to cutting shipping costs, the best void fill materials tick three key boxes: they’re lightweight, budget-friendly, and environmentally responsible. Paper-based materials, like kraft paper or packing paper, are a solid choice. They’re affordable, recyclable, and have a low environmental footprint. Plus, they protect your items while keeping the package weight down, which helps you avoid those pesky dimensional weight fees.

If you’re considering plastic options, air pillows or bubble wrap can do the job. However, they might not be the best pick for those looking to prioritize sustainability. To get the most savings, pair the right void fill material with packaging that fits snugly around your product. This way, you’ll use less filler, save money on shipping, and keep things greener at the same time.

How does Navexa's box optimization tool help lower dimensional weight fees?

Navexa's box optimization tool is designed to cut down on dimensional weight fees by ensuring packages are sized just right for their contents. This means less wasted space and fewer instances of oversized packaging, both of which can drive up shipping costs.

By precisely aligning box dimensions with the items being shipped, the tool helps lower the dimensional weight calculated by carriers - one of the key factors in determining shipping fees. The result? Reduced costs and a more efficient shipping process, helping you save money while keeping your fulfillment operations running smoothly.

Ready to optimize your fulfillment?

Start saving on shipping costs and streamline your operations with Navexa.