Optimizing Packaging to Lower Dimensional Weight Fees

Shipping costs are rising, and dimensional weight pricing is a major reason why. Carriers like FedEx, UPS, and USPS charge based on the size of your package, not just its weight. This means oversized or poorly packed boxes can inflate your shipping fees significantly.

Here’s the problem: DIM weight is calculated using the formula (Length × Width × Height) ÷ DIM Divisor, and carriers round up dimensions to the nearest inch. This can lead to higher billable weights, especially for lightweight, bulky items. For e-commerce businesses shipping thousands of packages, these costs add up fast.

Key Takeaways:

- Right-sizing packaging: Use boxes that fit your products more closely to reduce cubic volume and avoid paying for empty space.

- Switch to lightweight materials: Poly mailers, air pillows, or thinner cardboard can reduce both actual and dimensional weight.

- Leverage technology: Tools like dimensioning systems and AI-powered box optimization software can automate and improve packaging decisions.

- Audit your shipments: Regularly review carrier invoices for DIM upcharges and identify products that drive higher costs.

By optimizing your packaging strategy, you can reduce shipping costs by 10–20%, improve efficiency, and minimize waste. It’s not just about saving money - it’s about staying competitive in a market where every dollar counts.

Optimizing Carton Sizes for Increased Efficiency | E8

sbb-itb-ed0a9d1

How Oversized Packaging Increases Shipping Costs

How Box Size Impacts Shipping Costs: Dimensional Weight Comparison

Financial Costs of Inefficient Packaging

Using oversized boxes for shipping means paying for empty space - literally. Carriers like FedEx and UPS rely on dimensional weight pricing because their trucks often fill up on volume long before they hit their weight limits. Back in 2013, for instance, FedEx and UPS trucks, which can carry over 45,000 pounds, were routinely under 25,000 pounds because they were packed with low-density, oversized packages.

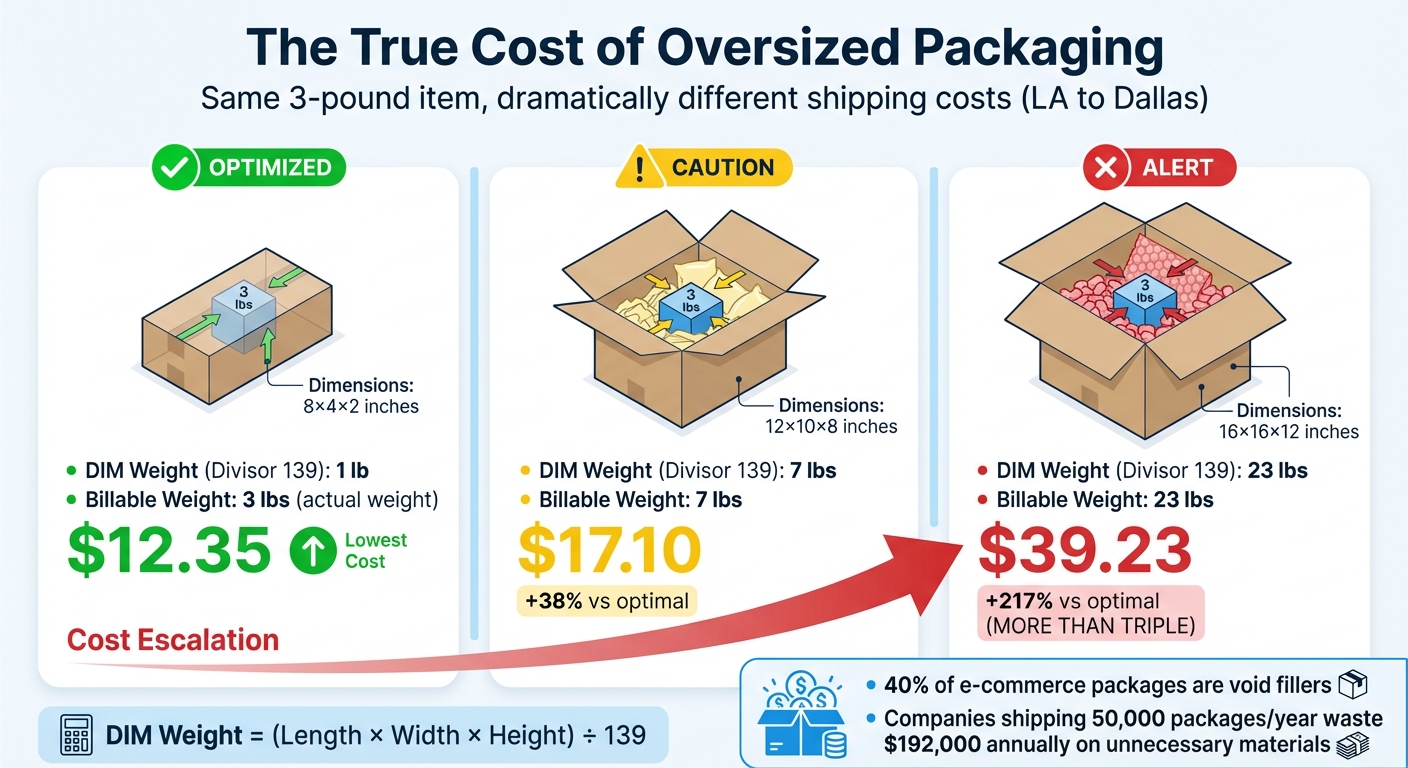

The financial consequences are staggering. Take a 3-pound item, for example. If shipped in a compact 8×4×2-inch box, the cost from Los Angeles to Dallas is about $12.35. But if you use a much larger 16×16×12-inch box for the same item, the dimensional weight skyrockets to 23 pounds, pushing the shipping cost to $39.23. That's more than triple the cost for the exact same product.

Here's a breakdown of how box size impacts costs:

| Box Dimensions | DIM Weight (Divisor 139) | Billable Weight | Estimated Cost (LA to Dallas) |

|---|---|---|---|

| 8×4×2 inches | 1 lb | 3 lbs | $12.35 |

| 12×10×8 inches | 7 lbs | 7 lbs | $17.10 |

| 16×16×12 inches | 23 lbs | 23 lbs | $39.23 |

And it’s not just the shipping fees. Oversized packaging inflates material costs too. On average, about 40% of an e-commerce package is made up of void fillers like bubble wrap, air pillows, or packing paper. For a company shipping 50,000 packages a year, this inefficiency could waste $192,000 annually just on unnecessary materials. To make matters worse, starting August 18, 2025, FedEx and UPS will round up any fractional inch to the next whole number, leading to even higher fees for slightly oversized boxes.

The ripple effects of oversized packaging don’t stop at costs - it also disrupts warehouse operations and reduces efficiency.

Operational Problems Caused by Oversized Packaging

Oversized packaging doesn’t just hit your wallet; it creates logistical headaches too. Roughly 50% of all parcels are not appropriately sized for their contents. Larger-than-necessary boxes take up valuable warehouse space, forcing frequent restocking of bulky shipping supplies and reducing storage efficiency. Fulfillment teams also waste time dealing with excess void fill for these oversized boxes.

Another issue is outdated procurement habits. Companies often stick with old box sizes that no longer fit their current product lineup. On top of that, logistics, purchasing, and sustainability teams frequently work in silos, missing opportunities to collaborate on optimizing packaging.

The consequences extend beyond the warehouse. Trucks filled with oversized packages "cube out" before they reach their weight capacity, leading to more vehicles on the road, increased fuel consumption, and higher carbon emissions. Items shipped in oversized boxes are also more likely to shift during transit, which increases the risk of damage, higher return rates, and additional customer service costs. Meanwhile, corrugated cardboard, which already makes up nearly 11% of U.S. municipal solid waste by weight, only adds to the waste problem when packaging is inefficient.

Strategies for Optimizing Packaging

Right-Sizing Packaging

One of the simplest ways to cut down on dimensional weight fees is to ensure your box size closely matches your product. Carriers calculate dimensional weight by multiplying the box dimensions (L×W×H) and dividing by a specific divisor, rounding each measurement to the nearest whole inch. Even a tiny adjustment - like a ¼-inch increase - can bump your package into a higher rate bracket.

"Even a ¼" can cause packages to get billed at higher weights than expected." - Sean Kim, VP of Parcel, Kase

Start by reviewing your current box inventory. Studies show that most businesses can handle 80% of their shipments with just 20% of their box sizes. Keeping six to ten box sizes on hand allows for versatility without overwhelming your storage. Multi-depth boxes, which come with pre-scored fold lines, are a smart choice - they can be adjusted to different heights, reducing the need for stocking too many unique box types.

A practical example of this approach comes from the beverage brand Hiyo. In 2025, they teamed up with fulfillment firm Kase to redesign their shipping boxes for their most popular product. By fine-tuning the box dimensions to reduce damage and eliminate unnecessary space, Hiyo managed to cut their overall fulfillment costs by more than 30%.

But the size of the box is only part of the equation - material choice plays a big role, too.

Using Lightweight and Durable Materials

Switching to lighter packaging materials can lower the actual weight of your shipments while reducing the need for oversized boxes. Materials like air pillows and polyethylene foam are excellent for protecting items without adding much weight. For less fragile products, such as clothing, poly mailers or padded mailers are great alternatives to heavier corrugated boxes, saving both weight and storage space.

If rigid boxes are necessary, opt for lighter options like C-flute corrugated cardboard, which balances durability with reduced weight. For void fill, air pillows are a standout choice - they provide solid bracing without unnecessary bulk. For fragile items, honeycomb paper products like GreenWrap offer biodegradable protection while remaining lighter than traditional heavy-duty inserts.

"Air pillows and polyethylene foam are the lightest packing materials, offering excellent protection for your items during transit." - eFulfillment Service

Using lightweight materials may seem like a small change, but these savings add up, especially at scale. Once your materials are optimized, the next step is to explore custom-fit solutions.

Implementing Custom-Fit Packaging Solutions

Custom-fit packaging takes the principles of efficient sizing and material selection to the next level, offering precision that minimizes waste and costs. It starts with creating digital SKU profiles using dimensioning equipment, which allows software to recommend the smallest possible container and reduces the chance of human error.

For businesses handling high volumes, on-demand box-making systems like Packsize or PackNet are game-changers. These systems use AI to cut custom cartons in real time, tailoring the box dimensions to fit the product perfectly. By doing so, they can reduce shipping volume by up to 40% and cut the need for dunnage by as much as 70%. Considering that the average shipping box is 40% larger than necessary, this approach can help businesses save 25% or more on shipping costs.

Even without advanced automation, visual packing instructions at workstations can make a difference. Displaying the recommended box size and necessary void fill on a screen helps employees consistently choose the right packaging.

Platforms like Navexa can further streamline the process by integrating intelligent box optimization features into your workflow. These tools automatically calculate dimensional weight and suggest the most cost-effective packaging for every shipment, helping you save time and money.

Using Technology to Reduce Dimensional Weight Fees

Box Optimization Platforms

When it comes to cutting down on dimensional weight fees, the right tools can make all the difference. Box optimization platforms take the uncertainty out of packaging decisions by using real-time data and AI-powered algorithms to recommend the smallest, most efficient container for each order. These platforms pull product dimensions directly from your database and integrate seamlessly with your order management system, automating the container selection process from start to finish.

For businesses handling high volumes, automated dimensioning hardware can be a game-changer. Take systems like vMeasure, for example. These devices can capture precise dimensions and weight in under two seconds, sending the data straight to your shipping software to calculate billable weight before printing a label. This automation eliminates human error in measurements. Starting at around $1,800, static dimensioning systems quickly pay for themselves by reducing shipping penalties.

Platforms like Navexa go a step further by embedding intelligent box optimization into your fulfillment workflow. They calculate dimensional weight and suggest the most cost-effective packaging for every shipment. This can help you avoid overpaying by as much as 25% on shipments due to oversized packaging. These tools provide the foundation for making smarter, data-driven decisions, as we’ll explore next.

Using Real-Time Analytics for Decision-Making

Data analytics can shine a spotlight on where your packaging strategy is costing you money. By analyzing shipment data and carrier invoices, you can identify products - often referred to as "usual suspects" - that frequently lead to dimensional weight overcharges. Monitoring these invoices for "DIM upcharge" flags helps pinpoint where redesigns or adjustments in packaging may be needed.

Advanced systems take it a step further by simulating various packaging configurations before you even start packing. This allows you to evaluate whether investing in custom-sized boxes for high-volume products might save more in the long run compared to using standard box sizes. Analytics also track carrier policy updates, such as changes in DIM divisors, so you can adapt your packaging strategy quickly to safeguard your profit margins.

One practical tip: Regularly auditing your invoices can reveal which SKUs are quietly draining your budget. Even slight measurement discrepancies can lead carriers to round up dimensions, significantly increasing billable weight - and your costs.

Automated Carrier Rate Shopping

Once you have actionable insights, automated carrier rate shopping can help you find the most cost-effective shipping options. These tools compare DIM divisors and other factors across multiple carriers. For instance, USPS uses a divisor of 166, while FedEx applies 139 for all services. Automated systems calculate the billable weight for each carrier and select the cheapest option for every shipment.

These tools also account for carrier-specific rules. For example, USPS uses a divisor of 166 across the board, while UPS switches between 166 for packages under one cubic foot and 139 for larger ones. On top of that, rate shopping software factors in hidden costs like residential delivery surcharges and fuel fees, which can add up to 30% of your total shipping expenses.

Negotiating DIM divisor adjustments with carriers can lead to savings of up to 16%. Many businesses also achieve 10–20% reductions through negotiations beyond standard rates. Platforms like Navexa simplify this entire process, automating rate comparisons and helping e-commerce brands cut shipping costs by 10–15% while eliminating the hassle of manual rate shopping.

Measuring Results and Validating Cost Savings

Baseline Shipping Analysis

Start by analyzing your historical shipping data to establish a baseline. One key metric is your "Blended Cost per Package", which you can calculate by dividing your total shipping spend by the number of packages shipped. This gives you a clear benchmark to measure improvements over time.

Next, dig into your carrier invoices. Compare the actual weight of each shipment to its dimensional (DIM) weight. Carriers charge based on the greater of the two, so this comparison helps you pinpoint where DIM weight is inflating your costs. Look for "DIM upcharge" flags on your monthly invoices - these often highlight specific SKUs where your packaging isn't optimized for carrier standards.

"Every brand that ships goods direct-to-consumer needs to be mindful of their dimensional weight of shipments. Most carriers will determine billable weight either by actual weight or scaled dimensional weight, whichever is higher."

- Sean Kim, VP of Parcel, Kase

Pay particular attention to "large but light" items, such as clothing or pillows. These products often have DIM weights that far exceed their actual weights, making them prime candidates for optimization. Sample some of your outgoing packages to assess how much void space they contain. On average, about 40% of a package's volume is filled with unnecessary materials like fillers, which directly contributes to higher shipping costs under DIM pricing formulas.

With this baseline data in hand, you’re ready to explore how packaging changes could reduce costs.

Scenario Modeling for Packaging Changes

Once you’ve established your baseline, use scenario modeling to test potential packaging adjustments. This involves running "what-if" simulations using your shipping data. For example, what happens if you shrink box dimensions by two inches or switch certain products from boxes to poly mailers?

Here’s a practical example: A package measuring 12″ × 12″ × 12″ with an actual weight of 2 pounds might be billed at 13 pounds under a DIM divisor of 139. By reducing the box size to 10″ × 8″ × 6″, the billable weight drops to just 4 pounds. Applying this kind of modeling across your product catalog can uncover SKUs with the highest savings potential.

When modeling, factor in carrier-specific rules. For instance, USPS uses a divisor of 166, while FedEx applies 139 across all services. For smaller packages (under 20 pounds and 0.5 cubic feet), consider USPS Cubic Pricing, which calculates rates based on size and shipping distance instead of weight.

In a real-world example, beverage brand Hiyo partnered with fulfillment provider Kase in September 2025 to address high shipping costs for their most-ordered SKU. By redesigning their shipper boxes to better fit the product and eliminate unnecessary space, they cut total fulfillment costs by more than 30%. This success story reinforces how right-sizing packaging can lead to significant savings.

After modeling changes, real-world results often validate the potential savings.

Case Studies of Cost Savings

Dimensional weight pricing impacts about 70% of all shipped packages, and businesses that optimize their packaging often reduce shipping costs by 10–20%.

"Shipping costs grew 35–50% from 2020–2023 due to capacity constraints, fuel surcharges, and carrier pricing power. Brands that didn't optimize saw shipping erode 3–5 points of margin - enough to turn profitable businesses unprofitable."

- Satish Jindel, Transportation Analyst, ShipMatrix

To track your progress, conduct Quarterly Business Reviews that evaluate volume commitments, check invoice accuracy, and compare rates to benchmarks. Automated invoice audits can also identify billing errors, often recovering 2–5% of your total shipping spend. Even small adjustments, like reducing a package’s dimensions by just one inch, can save tens of thousands of dollars annually.

Conclusion: Key Takeaways for Lowering Dimensional Weight Fees

Understanding dimensional weight pricing is crucial for keeping shipping costs under control. Carriers base their charges on the space a package occupies, not just its actual weight, and even small rounding adjustments can significantly increase fees.

One of the most effective strategies is right-sizing your packaging. Studies show that the average e-commerce package contains over 50% empty space, and nearly 25% of packages are almost twice as large as the items they hold. By right-sizing, you can shrink package dimensions by 40% and cut material usage by 26%. For soft goods like clothing, swapping bulky boxes for poly mailers can lower a package's billable weight from 5 pounds to its actual weight of 2 pounds.

Automated tools, like dimensioning systems and AI-powered box optimization platforms, are game-changers. They deliver precise measurements in seconds, eliminating human errors that could add unnecessary weight - sometimes as much as 5 pounds - to your billable total. Real-time analytics also allow you to track carrier invoices for dimensional weight upcharges and identify problematic SKUs.

Regular audits are essential to ensure continued savings. Keep an eye on your average shipping cost and compare billable weight to actual weight across shipments. Even a small measurement error, like 0.8 inches, can push a package into a higher rate tier, as carriers round up to the nearest whole inch.

Dimensional weight pricing is here to stay, and it's only becoming stricter. As Maxx Parrot aptly puts it:

"Right-sizing won't be a cost-saving initiative; it will be a survival metric".

Start optimizing your packaging today to protect your profit margins and improve operational efficiency.

FAQs

How do I choose the right box size to reduce dimensional weight fees?

To cut down on dimensional weight fees, start by measuring your product's dimensions - length, width, and height - in inches. Then, use the carrier's formula to calculate the dimensional (DIM) weight. For example, for domestic ground shipping, divide the product of the dimensions by 139. Once you have the DIM weight, compare it to the product's actual weight. The higher of the two will determine your shipping cost.

After that, choose a box that fits the product snugly, leaving minimal unused space. Ideally, the box should increase the overall volume by less than 10%. If you're managing a larger inventory, tools like Navexa’s built-in box optimizer can simplify this process. These tools automatically help you pick the most efficient packaging, potentially saving you 10-15% on shipping costs.

How can AI-powered box optimization software reduce shipping costs?

AI-powered box optimization software is transforming how e-commerce businesses manage shipping costs. By pinpointing the smallest, most efficient box for each product, this technology helps reduce dimensional weight (DIM) fees - a major factor in carrier pricing. Shrinking packaging size doesn’t just lower shipping expenses, often by double-digit percentages; it also trims down the use of filler materials and waste, aligning cost savings with eco-friendly practices.

Navexa’s fulfillment platform takes this a step further by integrating AI-driven box optimization into its suite of tools. It analyzes product dimensions in real time, selects the best-fit box, and pairs this with multi-carrier rate shopping. The result? Merchants not only cut DIM fees but also boost packing speed, accuracy, and overall fulfillment efficiency. On average, U.S. businesses using Navexa save 10–15% on shipping costs.

How can using lightweight materials help reduce shipping costs?

Reducing the weight of your shipments starts with using lightweight packaging materials. Pairing these materials with boxes that are the right size can also help lower the dimensional (DIM) weight - a factor carriers use to calculate shipping costs. Since shipping fees are typically based on the greater of the actual or DIM weight, cutting down on either one can translate into noticeable savings for your business.

Ready to optimize your fulfillment?

Start saving on shipping costs and streamline your operations with Navexa.