Ultimate Guide to Zone-Specific Delivery Optimization

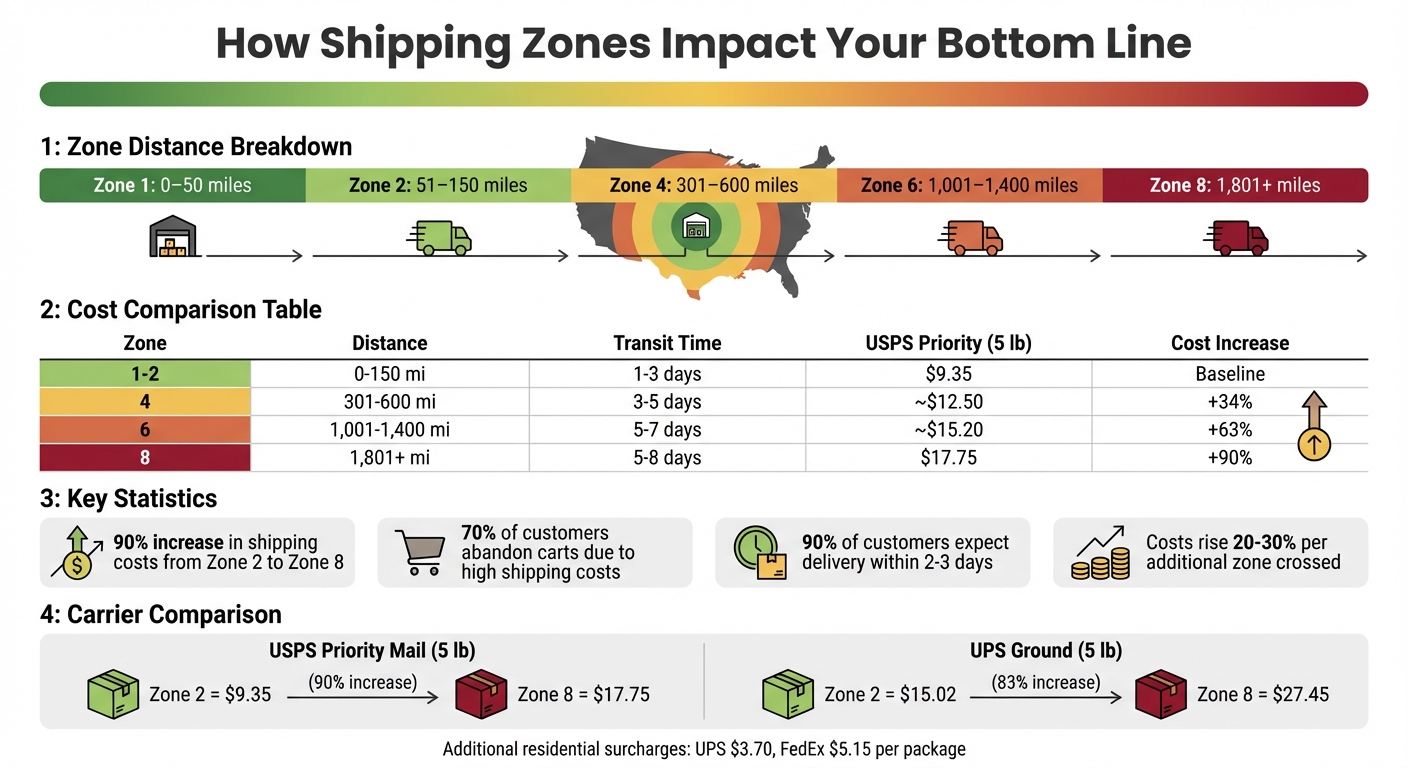

E-commerce businesses often struggle with shipping costs and delivery times, which vary based on customer location. Shipping zones, defined by carriers like USPS, UPS, and FedEx, significantly affect costs and transit times. For example, shipping a 5-pound package via USPS Priority Mail costs $9.35 in Zone 2 but jumps to $17.75 in Zone 8 - a nearly 90% increase. With 70% of customers abandoning carts due to high shipping costs, optimizing delivery by zones is crucial to maintaining profitability and meeting customer expectations.

Key takeaways:

- Shipping zones: Defined by distance from the warehouse, ranging from Zone 1 (0–50 miles) to Zone 8 (1,801+ miles).

- Cost impact: Shipping costs rise by 20-30% per additional zone crossed.

- Customer expectations: 90% expect delivery within 2–3 days.

- Strategies: Use multiple fulfillment centers, multi-carrier platforms, and zone skipping to reduce costs by 20–40% and improve delivery speed.

Understanding your customer distribution and leveraging tools like multi-carrier platforms or predictive analytics can lower shipping expenses and enhance delivery performance. This guide provides actionable strategies to help businesses save money, speed up deliveries, and meet customer demands.

How Shipping Zones Work in E-Commerce

Shipping Zone Cost and Transit Time Comparison Chart

Shipping zones are geographic areas used by carriers to determine delivery costs and transit times. Your fulfillment center is considered Zone 1, and zone numbers increase as the distance from that center grows. For example, a customer in Los Angeles might fall into Zone 2 for a Nevada warehouse but Zone 8 for a New York facility.

How Carriers Calculate Shipping Zones

Carriers calculate shipping zones based on the first three digits of both the origin and destination ZIP codes. These ZIP code prefixes group destinations by approximate distance. For instance:

- Zone 1: 0–50 miles from your warehouse

- Zone 2: 51–150 miles

- Zone 8: Over 1,801 miles away

Most domestic shipments in the U.S. fit into Zones 1 through 8. Zone 9, however, covers U.S. territories like Guam and American Samoa. While USPS, UPS, and FedEx all use similar zone structures, they differ in how they handle express services and shipments to Alaska, Hawaii, and Puerto Rico. These variations directly influence shipping costs and delivery times, as shown below.

How Zones Affect Shipping Costs and Delivery Speed

Shipping costs rise with distance. For example, shipping a 5-pound USPS Priority Mail package costs about $9.35 to Zone 2 but increases to $17.75 for Zone 8 - a nearly 90% jump. UPS Ground shows a similar pattern: the same package costs $15.02 for Zone 2 but climbs to $27.45 for Zone 8, an 83% increase.

Delivery times also lengthen with distance. Zones 1–2 typically see ground delivery within 1–3 days, while Zones 7–8 may take 5–8 days.

| Zone | Distance from Origin | Typical Ground Transit | Sample Cost (5 lb, USPS Priority) |

|---|---|---|---|

| Zone 1–2 | 0–150 miles | 1–3 days | $9.35 |

| Zone 4 | 301–600 miles | 3–5 days | ~$12.50 |

| Zone 6 | 1,001–1,400 miles | 5–7 days | ~$15.20 |

| Zone 8 | 1,801+ miles | 5–8 days | $17.75 |

This pricing structure can be a wake-up call for businesses.

"Weight and zones work together to create shipping cost scenarios that can shock businesses. We've seen companies discover they're losing money on every order to certain states simply because they never calculated the true landed cost including zone-based shipping".

Longer distances often require faster, more expensive shipping services, which can also disappoint customers expecting quick delivery. Costs can climb even higher for heavy or oversized items, and residential surcharges - around $3.70 per package for UPS and $5.15 for FedEx - can push the total cost difference between Zone 2 and Zone 8 well beyond 100%.

Understanding how zones impact costs and delivery times is key to developing strategies for managing these challenges, which will be addressed in the next section.

sbb-itb-ed0a9d1

Strategies for Optimizing Delivery by Zone

Now that we've covered how shipping zones influence both cost and delivery speed, let’s dive into ways you can minimize costs while maintaining efficient service. These strategies can help keep shipments in lower-numbered zones, which is key to managing expenses and meeting customer expectations.

Placing Fulfillment Centers Near Your Customers

One of the most effective ways to cut zone-based costs is by reducing the physical distance between your inventory and your customers. If you rely on a single warehouse, cross-country orders often land in higher-numbered zones like 7 or 8, which are more expensive to ship. By using multiple fulfillment centers, you can ship from the location closest to your customer, keeping most orders in Zones 1–3.

Here’s why this matters: last-mile delivery - the final leg of the shipping process - makes up a whopping 53% of total shipping costs. When you position warehouses near customer hubs, you not only lower this expense but also speed up deliveries. Orders in Zones 1–3 can often arrive within 1–2 days, compared to 4–6 days for orders in higher zones.

Start by analyzing your order history to find areas where your customers are most concentrated. Many e-commerce businesses succeed with a two-warehouse setup - one on the East Coast and one on the West Coast - covering the continental U.S. efficiently. Automating order routing ensures that shipments are sent from the nearest facility, saving time and reducing costs without requiring manual oversight.

Using Multi-Carrier Platforms for Better Zone Coverage

Not all carriers are created equal when it comes to zone coverage. While big names like UPS and FedEx offer national reach, they may charge higher rates for certain regions. On the other hand, regional carriers often provide faster and cheaper delivery for Zones 1 and 2.

This is where multi-carrier platforms shine. These tools compare rates across different carriers in real time, helping you choose the most cost-effective option for each shipment. By automating this process, you can avoid overpaying and even strengthen your negotiating position with carriers.

For instance, Navexa’s multi-carrier rate shopping feature integrates with over 50 e-commerce systems. It uses rules-based routing to balance cost and speed, prioritizing affordable options for non-urgent shipments while ensuring timely delivery for high-value orders. Diversifying your carriers also reduces risk - especially since 61% of shoppers say they’d switch retailers after just one failed delivery experience.

Applying Zone Skipping for High-Volume Orders

Another cost-cutting strategy is zone skipping, which consolidates multiple packages headed to the same region into a single freight shipment. Instead of sending each package individually across multiple zones, you transport them in bulk to a carrier hub near the destination. From there, the packages enter the local delivery network at regional rates.

"Zone skipping is a logistics strategy that consolidates shipments destined for the same region, reducing transit times and shipping costs by avoiding multiple sorting hubs." - Kristina Lopienski, Sr. Director of Marketing Communications, ShipBob

Zone skipping is particularly effective for high-volume orders in concentrated areas. Let’s say you’re shipping 2,000 packages to one region. By consolidating them, you could save around $3,000 - cutting costs from $10 per package (national rates) to $7 per package (regional rates), plus a single truckload fee. Transit times can also improve, dropping from 4–5 days to just 2–3 days by bypassing intermediate sorting hubs.

This method works especially well for subscription box companies or businesses with recurring shipments to the same regions. Use shipping data and heat maps to identify customer clusters that justify consolidated freight. If you’re a smaller business, partnering with third-party logistics providers (3PLs) can help you access better zone-skipping rates and infrastructure.

Setting Clear Delivery Expectations with Customers

Shipping costs and delivery times vary significantly depending on the zone, making it essential to set clear expectations with customers. Even with the most efficient fulfillment network, clarity around shipping costs and timelines is crucial. Why? Because 70% of shoppers abandon their carts due to unexpected shipping costs, and 24% cancel orders because of slow delivery.

The key to avoiding these pitfalls? Transparency. When customers are provided with accurate, zone-based delivery dates and costs upfront, they can make informed decisions without unpleasant surprises. This not only builds trust but also reduces cart abandonment. Keep in mind that 73% of shoppers expect both fast and affordable shipping, and 90% are only willing to wait two to three days for delivery. If your checkout process doesn’t reflect these expectations based on the customer’s location, you risk losing their business. Addressing these concerns directly at checkout aligns perfectly with earlier fulfillment strategies.

Showing Zone-Based Delivery Times at Checkout

Providing accurate, zone-based delivery dates at checkout is easier than you might think. Real-time shipping calculators make this possible. For instance, a customer in Zone 2 (within 150 miles of your warehouse) might see "Arrives in 1–2 business days", while someone in Zone 8 (over 1,800 miles away) could see "Arrives in 5–7 business days". This level of transparency eliminates surprises and helps customers feel confident in their purchase.

To make this seamless, use fulfillment platforms that integrate with your e-commerce system - like Shopify or WooCommerce. Tools such as Navexa’s multi-carrier rate shopping feature compare transit times across carriers in real-time, ensuring customers see the most accurate delivery estimates for their zone. Additionally, offering tiered shipping options (e.g., Standard: 5–7 days, Expedited: 2–3 days) allows customers to choose between speed and cost.

Don’t overlook internal processing times. For example, if your daily order cut-off time is 2:00 PM, orders placed after that should automatically adjust the delivery estimate by one business day. This small but important detail can prevent unnecessary complaints about "late" shipments that were actually on time. Such transparency reinforces trust and aligns with earlier fulfillment strategies.

Sending Clear Updates Based on Shipping Distance

Optimizing fulfillment centers and carrier choices can lower costs, but clear communication throughout the delivery process is what keeps customers happy. Tailor your updates to the shipping distance to manage expectations effectively. For example, orders headed to nearby zones might arrive the next day, while those going farther could take nearly a week. Customized notifications keep customers informed and satisfied every step of the way.

For nearby zones, a simple message like "Your order has shipped and will arrive tomorrow" works well. For longer distances, more detailed updates - such as "Your package has left our facility", "In transit to regional hub", and "Out for delivery" - can provide reassurance. This is especially useful if you’re using zone skipping, where packages consolidate temporarily before entering the local delivery network.

Automated systems make this process easy by sending time-stamped updates. Additionally, if delays arise due to weather or carrier issues, proactive alerts - like a "delivery delay notification" - can transform a potential complaint into an opportunity to build trust.

"Unclear shipping costs and delivery estimates frustrate customers and increase cart abandonment."

– Pitney Bowes

Tracking and Improving Zone Performance Over Time

Focusing on zone-specific delivery performance is crucial for optimizing costs and keeping customers happy. For direct-to-consumer brands, shipping expenses typically eat up 8–12% of total revenue - often surpassing marketing budgets. Regularly analyzing your shipping data helps you spot inefficiencies and turn those insights into actionable strategies. Think of your shipping data as a powerful tool, not just a byproduct of operations.

Analyzing Shipping Data for Cost and Time Patterns

A monthly review of your shipping data can reveal where your money is going and how well your deliveries are performing. Pay close attention to metrics like Average Shipping Zone, On-Time Delivery Percentage (aim for above 95%), Cost Per Package, and Transit Time by Zone. For instance, if a large chunk of your orders - say 40% - are heading to Zones 7 or 8, it might be time to consider opening a fulfillment center closer to those areas. Doing so could slash your average shipping zones by 30–40%.

Hidden costs can also sneak up on you. Surcharges like residential delivery fees, address corrections, and fuel surcharges (which can add 8–15% to the base rate) can quietly inflate your budget. Regularly track what percentage of your total shipping costs comes from these extra charges. Between 2020 and 2023, shipping costs rose by 35–50%, driven by capacity issues and fuel surcharges, making audits more essential than ever. Using automation to monitor these trends can help you make real-time adjustments and stay ahead of the curve.

"Stop treating shipping costs as a fixed expense. Your data reveals optimization opportunities hiding in plain sight."

– Alexander Jarvis

Automating Zone-Based Decisions with Technology

Once you’ve identified patterns in your data, automation can turn those insights into action. Manual analysis is not only time-consuming but also prone to errors. Modern fulfillment platforms simplify this process by automating tasks like comparing carrier rates, routing orders to the closest warehouse, and flagging underperforming carriers in specific zones. For example, Navexa’s multi-carrier rate shopping feature automates rate comparisons and carrier selection for each destination zone, cutting shipping costs by 10–15% while speeding up deliveries.

Predictive analytics is another game-changer. With 93% of shippers planning to increase their tech investments by 2026, predictive tools are becoming the norm. These systems can forecast delays and cost spikes, allowing you to act before problems arise. Set up automated alerts to notify your team if a carrier’s on-time delivery rate drops below 90% in a specific zone or if there’s a rise in "Where Is My Order" (WISMO) inquiries in a certain region. These alerts enable you to reroute shipments, switch carriers, or adjust inventory placement proactively.

The stakes are high: 84% of customers say they wouldn’t shop with a retailer again after a single poor delivery experience. Automation isn’t just about saving money - it’s about preserving your brand’s reputation. By combining data insights with automated systems, you can move seamlessly from identifying opportunities to implementing solutions, ensuring your zone-specific delivery strategy stays sharp and effective.

Conclusion

Zone-specific delivery strategies are a game-changer for e-commerce businesses aiming to stay competitive. By understanding shipping zones and applying targeted methods, companies can slash shipping costs by 20–40%, achieve delivery times as quick as 1–2 days, and safeguard their profit margins from the challenges of long-distance shipping.

The tactics outlined in this guide - like strategically locating fulfillment centers near customer hubs and using zone skipping for high-volume routes - help streamline shipping operations. Together, these approaches not only cut costs but also ensure faster deliveries and maintain customer trust.

Tools like Navexa simplify the process by automating rate comparisons, order routing, and analytics. This automation can reduce shipping expenses by 10–15%, speed up delivery times, and enhance customer satisfaction. With such tools, businesses no longer need to manually calculate zones, compare carrier rates, or sift through countless ZIP codes.

Analyzing customer ZIP code data is another crucial step in refining your fulfillment strategy. As Claudine Mosseri from J&J Global Fulfilment explains:

"Most businesses have no idea how their customers are distributed across shipping zones... when we analyze their actual ZIP codes, we often find the majority of orders going to just three or four zones".

This type of analysis can reveal opportunities for major savings and help reshape how you approach order fulfillment. By leveraging these insights, e-commerce brands can create a more efficient operation and build a foundation for long-term profitability.

FAQs

How do I find my average shipping zone?

To figure out your average shipping zone, start by analyzing where your shipments are headed. Use carrier zone charts to determine the zone for each destination. Add up all these zone numbers and then divide the total by the number of shipments. The result is your average zone, which can help fine-tune your delivery strategies.

When should I add a second fulfillment center?

If you're grappling with high shipping costs, long delivery times, or unhappy customers, it might be time to think about opening a second fulfillment center. Some clear signs include having a warehouse that's too far from a significant portion of your customers, seeing a steady increase in order volumes, or dealing with bulky products that drive up shipping expenses. Adding another location strategically can help cut transit times, bring down shipping costs, and meet customer expectations - especially when quick delivery options like two-day shipping are falling short.

Is zone skipping worth it for my order volume?

Zone skipping can help cut costs, especially if you're dealing with a high volume of orders or your customers are clustered in specific regions. By consolidating shipments and skipping intermediate shipping zones, businesses can save significantly - sometimes more than $20 per package. On top of that, it can speed up delivery since transit times are reduced. That said, if your orders are smaller in volume or scattered across various locations, the complexity of setting up zone skipping might outweigh the potential savings, making it a less practical option.

Ready to optimize your fulfillment?

Start saving on shipping costs and streamline your operations with Navexa.