Dimensional Weight Pricing: What E-Commerce Brands Need to Know

Dimensional weight pricing determines shipping costs based on package size rather than just weight. Carriers like FedEx, UPS, and USPS calculate this using a formula: (Length x Width x Height) ÷ DIM Divisor = Dimensional Weight. The higher of the dimensional or actual weight becomes the "billable weight." This pricing model significantly impacts e-commerce businesses, especially for lightweight items in large boxes.

Key Points:

- DIM Divisors Matter: FedEx and UPS use a divisor of 139, while USPS often uses 166. A higher divisor reduces shipping costs.

- New Rules: Since August 2025, carriers round up fractional inches, increasing billable weight.

- Cost-Saving Tips:

- Use snug packaging or poly mailers.

- Implement box optimization tools.

- Negotiate higher DIM divisors with carriers.

- Regularly review packaging to minimize wasted space.

Understanding dimensional weight pricing helps you control shipping costs and maintain profitability.

How Dimensional Weight is Calculated

The Dimensional Weight Formula

Figuring out dimensional weight isn’t complicated. Start by measuring each side of the package in inches, including any bulges or irregularities. Round up any fractions to the next whole number (for example, 11.1 inches becomes 12 inches). Then, multiply the length, width, and height to calculate the package’s cubic size. Finally, divide that total by the carrier’s DIM divisor to get the dimensional weight in pounds. Don’t forget to round up to the nearest whole pound.

For context, FedEx and UPS Daily Rates use a divisor of 139, while UPS Retail Rates and USPS use 166. A higher divisor means a lower dimensional weight, which can reduce shipping costs. After calculating, the carrier compares the dimensional weight to the actual weight and charges based on the higher of the two. This is known as the billable weight. Let’s look at a few examples to see how this works in practice.

Dimensional Weight Calculation Examples

Here are some examples to show how dimensional weight can affect shipping costs:

- Package 1: A box measuring 30 inches by 12 inches by 12 inches has a volume of 4,320 cubic inches. Divide 4,320 by 139 (the divisor), and you get approximately 31.15, which rounds up to 32 pounds. If the actual weight is 29 pounds, the billable weight is 32 pounds.

- Package 2: A smaller box measuring 12 inches by 15 inches by 7 inches has a volume of 1,260 cubic inches. Dividing by 139 gives 9.07, which rounds up to 10 pounds. If the actual weight is only 5 pounds, the billable weight is still 10 pounds.

- Package 3: A larger box measuring 24 inches by 18 inches by 12 inches has a volume of 5,184 cubic inches. Dividing by 139 results in about 37.25, which rounds up to 38 pounds. Even if the actual weight is just 10 pounds, the billable weight is 38 pounds - almost four times the actual weight.

These examples highlight how shipping lightweight items in large boxes can become much pricier. For instance, a 10x10x10-inch box (1,000 cubic inches) would bill at 8 pounds with a divisor of 139, but only 7 pounds with a divisor of 166.

What is Dimensional Weight and How Do You Calculate It?

DIM Divisors by Carrier

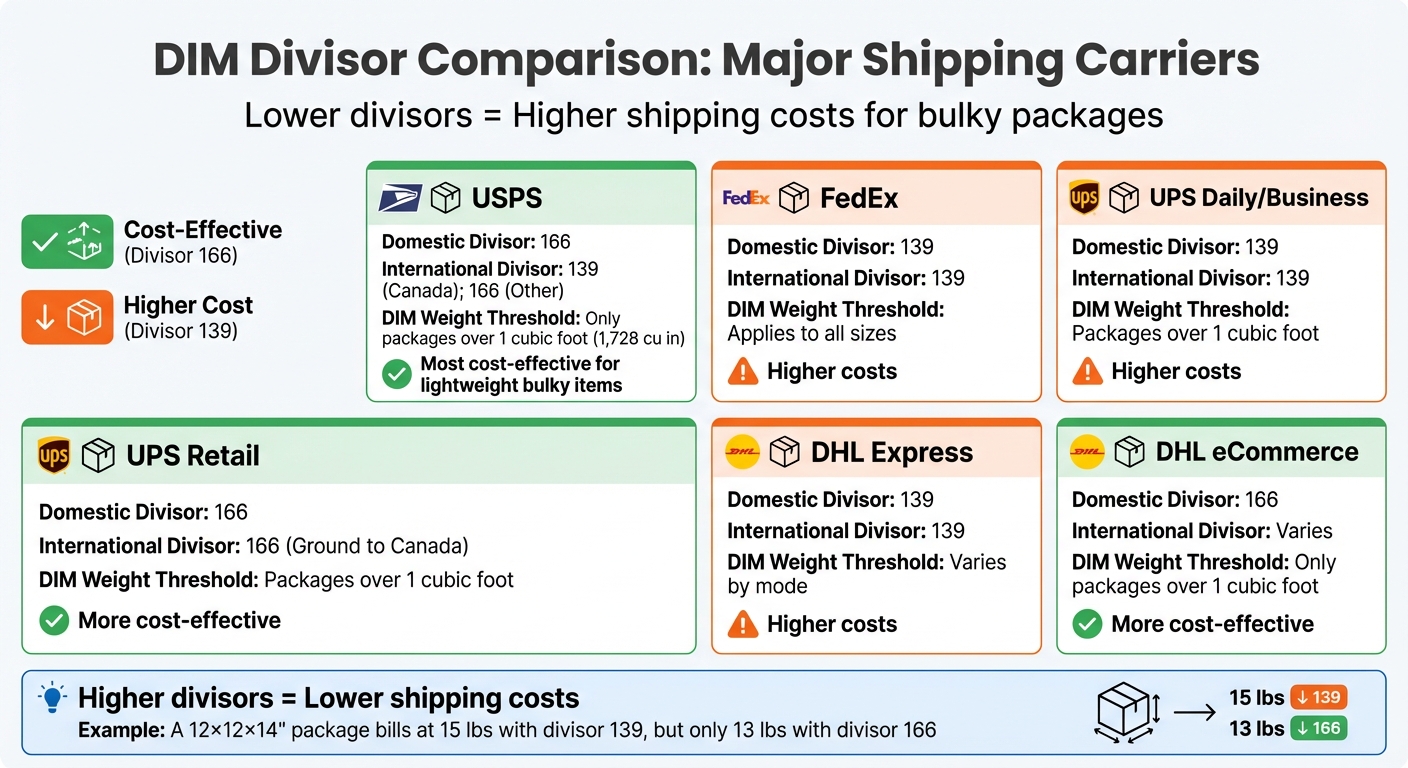

DIM Divisor Comparison by Major Shipping Carriers

Major Carrier DIM Divisor Comparison

Carriers don't all follow the same rules when it comes to DIM (dimensional) divisors, and these differences can have a noticeable effect on your shipping costs. For example, FedEx and UPS use a domestic DIM divisor of 139, which tends to raise shipping costs for lightweight but bulky items. On the other hand, USPS generally uses a divisor of 166 for most domestic shipments, making it a more budget-friendly option for large, lightweight packages.

Here’s a quick breakdown of DIM divisors by major carriers:

| Carrier | Domestic Divisor | International Divisor | DIM Weight Threshold |

|---|---|---|---|

| USPS | 166 | 139 (Canada); 166 (Other) | Only for packages over 1 cubic foot (1,728 cu in) |

| FedEx | 139 | 139 | Applies to all sizes |

| UPS Daily/Business | 139 | 139 | Packages over 1 cubic foot |

| UPS Retail | 166 | 166 (Ground to Canada) | Packages over 1 cubic foot |

| DHL Express | 139 | 139 | Varies by mode |

| DHL eCommerce | 166 | Varies | Only for packages over 1 cubic foot |

USPS only applies dimensional weight pricing to packages that exceed one cubic foot in volume. This variability underscores how choosing the right carrier can directly affect your shipping costs and billable weights.

How Carrier Choice Affects Costs

The choice of carrier plays a crucial role in determining your shipping expenses, especially for lightweight, bulky items. Let’s say you’re shipping a package that measures 12 inches by 12 inches by 14 inches. With FedEx or UPS, which use a 139 divisor, the package might be billed at 15 pounds. However, USPS, with its 166 divisor, would only bill it at 13 pounds. That 2-pound difference might not seem like much, but it can add up quickly when shipping in volume.

"Carriers use a DIM divisor (typically 139 for domestic shipments), but high-volume shippers often negotiate higher divisors, thereby reducing chargeable weight." - Robert Khachatryan, CEO and founder, Freight Right Global Logistics

For businesses shipping in large volumes, negotiating a higher divisor - like moving from 139 to 166 - can lead to significant cost savings. Third-party logistics providers often secure divisors as high as 166 for domestic orders within the U.S., potentially cutting shipping costs by as much as 37%.

sbb-itb-ed0a9d1

How to Reduce Dimensional Weight Fees

Use Right-Sized Packaging

One of the simplest ways to lower dimensional weight fees is by choosing packaging that fits your product snugly. Extra space in a box increases its cubic volume, which leads to higher shipping costs. For lightweight, non-fragile items like clothing, consider using poly mailers or padded envelopes to avoid dimensional weight penalties. Similarly, soft goods like pillows or bedding can be vacuum-sealed to take up less space. By selecting the right-sized box for each product, you can start cutting unnecessary shipping expenses. From there, incorporating technology can take your packaging strategy to the next level.

Use Box Optimization Tools

Box optimization software, often called cartonization, helps you pick the most space-efficient packaging for your products. Tools like Navexa’s intelligent box optimization analyze your orders and recommend the best box size from your inventory, helping you avoid oversized shipments that rack up extra fees. For example, in November 2025, Waveform Lighting worked with their fulfillment partner to review their order history. They identified custom box sizes for products with unusual dimensions, reducing empty space and cutting dimensional weight costs. Similarly, Hiyo redesigned their shipper boxes for their most popular product, slashing fulfillment costs by over 30%.

"ShipBob supplied a range of standard box sizes, but because some of our products have such unusual dimensions, some of our shipments were being sent out with lots of empty space, leading to higher shipping costs." - Waveform Lighting Team

While technology plays a big role, negotiating with carriers can also lead to significant savings.

Negotiate Carrier Rates Based on Volume

For businesses shipping large volumes, negotiating a higher DIM divisor - like moving from 139 to 166 - can make a big difference in costs. Start by running a parcel analysis to understand your package dimensions and see how many shipments are affected by dimensional weight pricing. Use this data to negotiate better rates with carriers or work with third-party logistics providers that already have pre-negotiated discounts.

Review Packaging Regularly

Your packaging strategy shouldn’t be static. Conduct regular audits to pinpoint products that frequently result in dimensional weight charges and adjust your box sizes as needed. Pay special attention to product bundles, as a small, oddly shaped promotional item can force an entire order into a larger, more expensive box. Always ensure your team selects the smallest protective box that fits the product properly. Don’t forget to measure boxes from the outside at their widest points, including any bulges, to ensure accurate calculations.

Key Takeaways

Dimensional Weight Summary

Dimensional (DIM) pricing calculates shipping costs based on the size of a package rather than its actual weight. Carriers determine charges using the greater of the actual weight or the dimensional weight, which is calculated using carrier-specific divisors like 139 or 166. This approach impacts most shipments, making it a major expense for e-commerce businesses.

One important detail is that carriers now round up package dimensions, which can push shipments into higher pricing tiers. To keep DIM fees under control, businesses should focus on using appropriately sized packaging, opt for poly mailers when shipping soft goods, and consider box optimization tools to reduce wasted space. High-volume shippers may also negotiate better DIM divisors with carriers or collaborate with fulfillment providers that offer discounted rates. Regularly auditing packaging can help pinpoint products - like bundles with small promotional items - that may unnecessarily result in oversized packaging and higher costs.

These strategies form the foundation for reducing shipping expenses, as outlined in the next section.

How Navexa Reduces Shipping Costs

Navexa applies these DIM strategies to help businesses lower their shipping expenses. Its box optimization feature ensures the most compact packaging is chosen, reducing excess space that leads to higher DIM charges. Additionally, Navexa's multi-carrier rate shopping tool compares real-time rates from FedEx, UPS, USPS, and other carriers. It takes into account each carrier’s DIM divisors and pricing rules, ensuring you find the most cost-effective shipping option. Together, these tools typically cut shipping costs by 10–15% while also simplifying fulfillment processes.

FAQs

How can I negotiate a better dimensional weight (DIM) divisor with my shipping carrier?

Negotiating a more favorable DIM divisor with your carrier comes down to showing how it’s a win-win situation. Start by digging into your shipping data. Compare your packages’ actual weights to their DIM weights (calculated using the standard divisor, like 166 in³/lb). Highlight how the current divisor impacts your costs. Then, calculate potential savings if a higher divisor, such as 200 in³/lb, were applied. These numbers will form the backbone of your argument.

Next, leverage your shipping volume and growth potential. Carriers are more inclined to negotiate with businesses that ship in high volumes or show promising growth. Prepare a clear, data-driven proposal that outlines the benefits of a higher divisor for both sides. If your carrier seems reluctant, consider proposing a trial period to test the new divisor and track its impact.

To strengthen your case, tools like Navexa can be invaluable. They provide real-time rate comparisons and help optimize box usage, illustrating how the adjustment can improve efficiency across the board. This kind of data can make your negotiation more persuasive and grounded in measurable results.

How can e-commerce brands reduce dimensional weight shipping fees?

To keep dimensional weight (DIM) fees in check, start by selecting the smallest box that can safely hold your products. By cutting down on unused space, you reduce the package's billable volume. Use just enough cushioning - like thin paper or molded inserts - instead of bulky materials that unnecessarily increase the size and weight.

Another smart move is consolidating multiple items into a single package. This improves density and shifts the billable weight calculation from DIM to the actual weight of the package. You can also save by opting for lightweight yet sturdy materials, such as thinner cardboard or recyclable mailers.

For an even more efficient approach, consider using a fulfillment platform like Navexa. It offers intelligent box optimization, helping you choose the most cost-effective packaging for each order. When combined, these strategies can significantly lower shipping costs and boost your bottom line.

How can choosing the right shipping carrier help reduce costs?

Choosing the right shipping carrier can have a big impact on your overall costs. Each carrier applies its own dimensional weight (DIM) factor, rounding methods, and pricing strategies, all of which can influence how much you pay. DIM weight is determined by multiplying a package’s length, width, and height, and then dividing by a specific divisor set by the carrier (e.g., 139 for many domestic shipments). A larger divisor means a lower DIM weight - and potentially lower shipping costs - while smaller divisors or stricter rounding rules can lead to higher charges.

Carriers also differ in their base rates, distance-related fees, and premiums for faster delivery services. As a result, the same package might cost more with one carrier than another. Using a multi-carrier rate comparison tool, like Navexa, makes it easy to weigh your options in real time. These platforms can automatically select the most budget-friendly carrier, helping you save an average of 10-15% on shipping costs without compromising on delivery timelines.

Ready to optimize your fulfillment?

Start saving on shipping costs and streamline your operations with Navexa.