Dynamic Labeling for Multi-Carrier Shipping

Dynamic labeling simplifies and speeds up the shipping process by automating label generation and carrier selection. It connects directly to carrier APIs (like USPS, UPS, FedEx, and DHL) to pull real-time rates, validate addresses, and ensure compliance with carrier standards. Businesses can save time, reduce errors, and cut costs by up to 90% compared to manual methods. Here’s why it matters:

- Faster Processing: Labels are created in under 10 seconds, compared to 30 seconds manually.

- Cost Savings: Real-time rate comparisons and pre-negotiated discounts lower shipping costs.

- Scalability: Handles thousands of shipments daily, including international orders.

- Accuracy: Built-in address validation and compliance prevent delivery failures and extra fees.

Revolutionizing Shipping with CloudLeap | Piyovi Multi-Carrier Shipping Platform Overview

What is Dynamic Labeling?

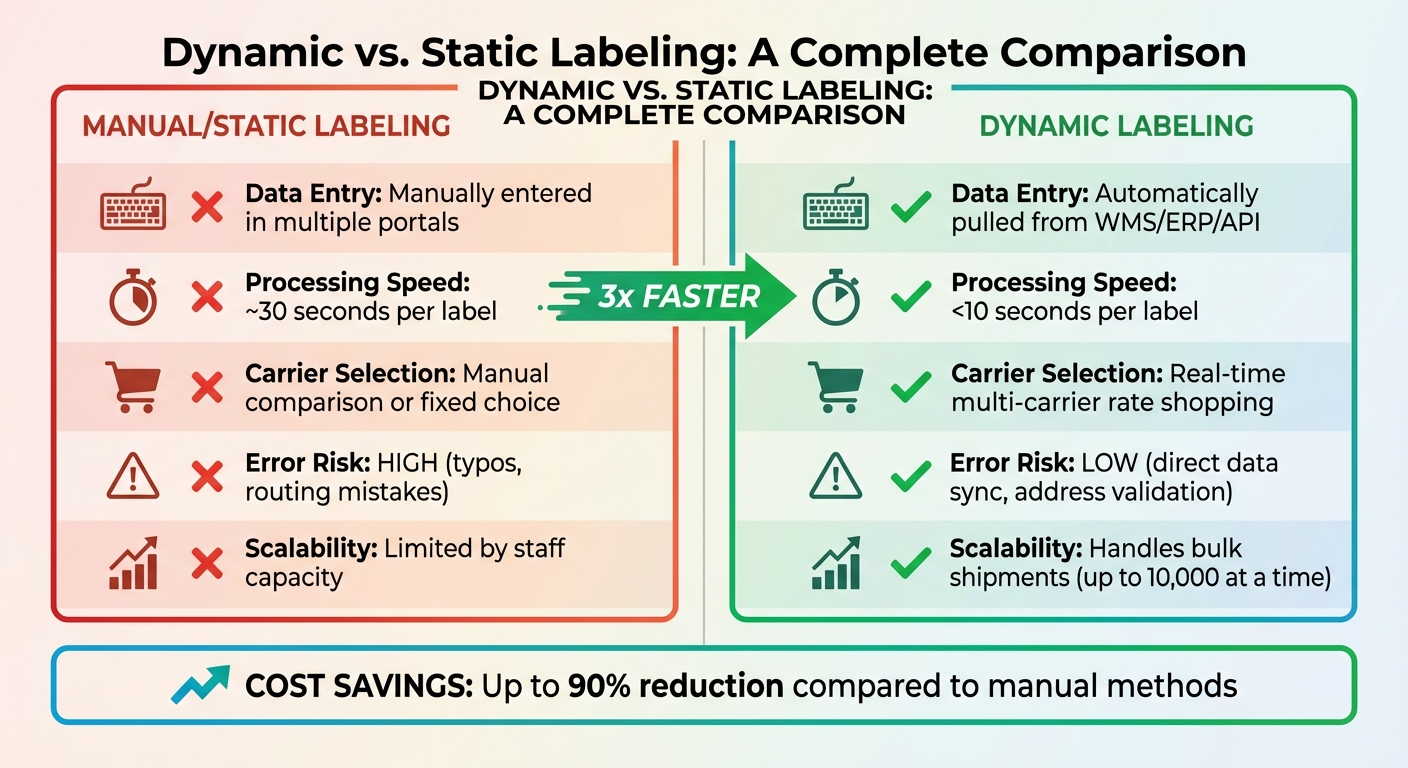

Dynamic vs Static Labeling: Speed, Cost and Efficiency Comparison

Dynamic Labeling Defined

Dynamic labeling is an automated process that creates compliant shipping labels in real time by pulling shipment data. It gathers details like the recipient's address, package weight, and dimensions directly from your WMS, ERP, or e-commerce platform.

What sets dynamic labeling apart is how it generates the label. As soon as an order comes in, the system taps into the required data - customer address, package dimensions, and weight - and instantly produces a properly formatted label. This includes a unique, scannable barcode that works seamlessly with carriers like USPS, FedEx, and UPS.

Modern systems go a step further by handling complex compliance rules automatically. They generate carrier-specific barcodes and include required service icons, all in one streamlined process. To keep up with changing carrier requirements, top shipping infrastructure providers dedicate over 3,500 hours annually to maintaining compliance, ensuring labels remain valid.

This automated process highlights the efficiency of dynamic labeling compared to manual methods.

Dynamic vs. Static Labeling

Dynamic labeling eliminates the manual steps required in static methods. With static or manual labeling, you have to log into each carrier’s portal, re-enter shipping details already stored in your system, and manually compare rates. This approach is time-consuming, repetitive, and prone to errors like typos in addresses or routing details.

| Feature | Manual/Static Labeling | Dynamic Labeling |

|---|---|---|

| Data Entry | Manually entered in multiple portals | Automatically pulled from WMS/ERP/API |

| Processing Speed | Around 30 seconds per label | Less than 10 seconds |

| Carrier Selection | Manual comparison or fixed choice | Real-time multi-carrier rate shopping |

| Error Risk | High (e.g., typos, routing mistakes) | Low (direct data sync, address validation) |

| Scalability | Limited by staff capacity | Handles bulk shipments (up to 10,000 at a time) |

Thanks to its speed and accuracy, dynamic labeling is particularly effective for businesses managing high shipping volumes or multiple carriers.

How Dynamic Labeling Works with Multi-Carrier Systems

Dynamic labeling thrives in a multi-carrier setup. It connects to various carrier APIs, retrieves live shipping rates, and ensures the label meets the formatting and compliance standards of the selected carrier. The system compares real-time rates across carriers, identifies the best option, and generates the label all in one step.

For businesses with a preferred carrier and service level, dynamic systems offer “Instalabel” or single-call label creation, which skips the rate comparison and generates a label instantly. A single integration with a multi-carrier API can provide access to over 40 carriers and 500+ service levels, removing the need to establish and maintain individual connections with each carrier.

Address validation is another key feature. The system automatically corrects errors before finalizing the label, helping businesses avoid failed deliveries and reprocessing fees. This level of integration not only simplifies label creation but also enhances the overall shipping workflow. Dani Arnout, CTO of Flyp, summed up the benefits of this approach:

"Companies like Shippo are bridging the gap between carriers and users. It's so hard to even talk to carriers, let alone integrate with them. With Shippo, in a couple hours we were ready to have a label generation machine that integrates with all the carriers."

Benefits of Dynamic Labeling for E-Commerce

Navexa incorporates dynamic labeling technology into its all-in-one fulfillment platform, helping e-commerce businesses simplify multi-carrier shipping, make smarter carrier choices, and cut costs in significant ways.

Better Carrier Selection

Dynamic labeling pulls live carrier rates for every order and compares them automatically. Instead of juggling static spreadsheets or manually comparing rates, the system evaluates factors like cost, delivery speed, and transit time.

You can set up automated rules to match your shipping priorities. For instance, you might configure the system to always pick the cheapest option for standard orders or prioritize speed for expedited shipping. This automation removes the need for manual comparisons and ensures every package ships at the best price.

Using multiple carriers also adds built-in redundancy. If one carrier faces delays or capacity issues - especially during peak seasons - the system can immediately shift shipments to another provider.

By optimizing carrier selection, businesses can save money and process orders more efficiently.

Lower Costs and Faster Processing

Automation speeds up order processing, clears backlogs, and boosts warehouse efficiency.

Dynamic labeling also helps prevent costly mistakes. For example, address validation catches and fixes errors instantly, avoiding failed deliveries, return-to-sender fees, and carrier correction charges. Some systems even include carrier invoice reconciliation, which compares quoted label costs with final invoices to flag discrepancies, unexpected fees, or weight adjustments.

Batch processing further improves efficiency, and pre-negotiated shipping discounts can save up to 90% on costs.

This level of automation not only reduces expenses but also sets the stage for highly accurate deliveries.

Improved Delivery Accuracy

Address validation plays a key role in ensuring delivery accuracy. By verifying recipient details before generating a label, the system prevents mistakes that could lead to mis-shipments, delays, or unhappy customers. It corrects formatting errors and flags incomplete addresses, ensuring packages reach their destination on the first try.

Dynamic systems also ensure carrier-specific compliance standards are met, formatting labels to adhere to regulations like HIPAA or FDA requirements for healthcare shipments. This is critical, especially since 65% of online shoppers now expect delivery within 2–3 days, and 72% of customers satisfied with delivery service are likely to increase their spending with a brand by 12%.

By automating validation and compliance, businesses can achieve reliable, first-attempt deliveries. As Simon Vincent, CEO of Joggles, explains:

"The less I have to think about our shipping API provider, the better. It means everything is performing exactly as it should".

Core Features of Dynamic Labeling Systems

Navexa incorporates dynamic labeling into its all-in-one fulfillment platform, helping e-commerce businesses streamline multi-carrier shipping. These tools automate tedious parts of label creation while ensuring compliance with the specific standards of hundreds of carriers. This builds on earlier automation principles, improving efficiency and accuracy in managing shipping tasks.

Automated Label Generation

Dynamic labeling systems simplify the creation of carrier-compliant labels for over 400 parcel, LTL, and FTL carriers, including major names like UPS, FedEx, DHL, and regional providers.

Using rules-based automation, the system applies predefined conditions - like package weight, destination ZIP code, or service level - to automatically select the best carrier and shipping method for each order. High-volume operations benefit from batch processing, allowing multiple labels to be generated simultaneously through CSV uploads or API integrations. This can cut processing times dramatically, with some systems operating up to 50% faster than standalone software. Address validation is built in, catching errors before printing to avoid failed deliveries or expensive corrections. For multi-package shipments, the system not only assigns carriers but also prepares customs declarations and other required documents for international shipping.

To complement label creation, real-time rate shopping ensures businesses get the best shipping rates.

Real-Time Rate Shopping

Real-time rate shopping retrieves live shipping rates from carrier APIs and displays them side by side. It factors in base rates, fuel surcharges, and dimensional weight (DIM) calculations to provide a clear view of the total cost for each option. The system also compares service levels - such as overnight, 2-day, and ground - so businesses can balance cost with delivery speed to meet customer expectations. Automated rules help select the best carrier based on criteria like cost or speed. For added cost control, invoice reconciliation tools compare the rate quoted at label generation with the final billed amount, flagging any discrepancies or unexpected surcharges.

Businesses can also take advantage of USPS Commercial Rates and other discounts, which can offer savings of up to 90% off retail prices. Integrated parcel shipping typically reduces overall costs by 15–30% on average. This cost-effective approach seamlessly ties into the dynamic labeling process.

"Dynamic Ship completely transforms how businesses handle shipping in Business Central. From real-time rate shopping to automated package tracking, this app streamlines logistics, improves customer satisfaction, and saves businesses time and money".

Special Shipping Requirements

Dynamic labeling systems are equipped to handle shipments with unique compliance needs or documentation. For international orders, the system generates customs declarations, commercial invoices, and air waybills by automatically pulling order data into the required forms, helping to avoid border delays. When dealing with hazardous materials, automated service indicators ensure compliance, such as USPS labels displaying the "H" symbol for HazMat shipments.

Special handling instructions, including signature requirements, Saturday delivery, or perishable goods designations, can be added directly to labels. For temperature-sensitive shipments, moisture-resistant poly labels ensure durability, even in high-condensation environments. Additionally, the system supports specialized labels, like those with hot-melt adhesives for non-corrugated surfaces such as wood or plastic, ideal for items like tires or crates. These features ensure that whether you're shipping prescription medications, frozen foods, or industrial chemicals, your labels meet both carrier and regulatory standards right from the start.

sbb-itb-ed0a9d1

Integrating Dynamic Labeling with Fulfillment Operations

Bringing dynamic labeling into your fulfillment operations streamlines the entire shipping process. Instead of handling shipping as a separate task, this integration makes label generation a seamless part of your workflow. The result? Reduced manual data entry, fewer errors, and a smoother connection between back-end operations and real-time shipping execution.

Connecting with Warehouse Tools

Modern dynamic labeling systems are designed to integrate effortlessly with warehouse management systems (WMS) and inventory platforms using standardized REST APIs. This setup enables real-time data exchange between order sources and shipping carriers. When an order is ready to ship, the WMS automatically transfers key details - like weight, dimensions, and service requirements - to the labeling engine, leveraging structured data such as shipment and address information.

To ensure accuracy, the system uses unique identifiers like warehouse_id to organize labels by warehouse location. This ensures that end-of-day manifests align with the correct "Ship From" address, which is especially important for businesses managing multiple fulfillment centers. It prevents errors like labels being generated with the wrong origin address.

Dynamic labeling systems also support various label formats to accommodate different warehouse printers. For high-volume operations, batch processing can generate hundreds or even thousands of labels at once, dramatically cutting down on manual effort. Some multi-carrier APIs can even handle up to 10,000 shipments in a single request.

Integrated address validation at the order entry stage helps prevent delivery failures by verifying destination details before labels are generated. This not only saves on label costs but also reduces the chances of shipping errors. Once created, labels remain accessible for up to 72 hours, allowing for programmatic retrieval if needed.

Multi-Carrier API Integration

Standardized API integration simplifies the process of connecting with multiple carriers. Instead of building separate connections for each carrier, businesses can access dozens of carriers through a single API, reducing the complexity and overhead of managing individual integrations.

These APIs deliver consistent response formats across carriers, including tracking numbers, label URLs, and cost details, making it easier to manage shipments. During the setup of a new WMS integration, testing tools like sandbox environments allow businesses to generate test labels without incurring carrier charges. For operations with standard packaging, pre-defined parcel templates for common box sizes can further streamline API requests by minimizing the required data for each shipment. Additionally, ensuring that phone numbers are formatted correctly for the destination country can help avoid errors during label generation.

Automated Workflows

Automated workflows take the repetitive tasks out of the shipping process. For businesses shipping over 40,000 packages annually, moving from manual web apps to API-integrated batch processing can significantly speed up service level selection and label generation.

These workflows handle everything from requesting shipping rates to logging shipment data and generating final labels once orders are packed. They also work seamlessly with multi-carrier and warehouse integrations. For example, the system can automatically retrieve the label_url and tracking_number from the API response, update the WMS, and trigger customer tracking notifications.

Labels flagged as eligibleForManifest are automatically included in end-of-day carrier reports. Integrated systems also allow for programmatic voiding or cancellation of labels if an order is changed or canceled, all from within the WMS interface. For shipments involving multiple packages, advanced integrations can generate "parent" and "child" tracking numbers, grouping packages under a single shipment for discounted rates.

Platforms like Navexa incorporate these automated workflows into their fulfillment tools, connecting with over 50 e-commerce platforms. This API-driven approach reduces the time warehouse teams spend on manual label creation, allowing them to focus on more impactful fulfillment tasks.

Using Analytics to Improve Dynamic Labeling Performance

Dynamic labeling turns shipping data into actionable insights, transforming shipping from a simple cost center into a powerful strategic tool. Instead of reacting to problems after they’ve already hurt your bottom line, analytics help you spot trends, adjust carrier partnerships, and address issues before they escalate.

Monitoring Shipping Metrics

The first step to better shipping performance is tracking key metrics like on-time delivery rates, cost per shipment, and exception rates. Modern dynamic labeling systems consolidate data from all your carriers into one dashboard, making it easier to compare performance side by side. This centralized view helps you identify which carriers consistently deliver on their promises and which ones fall short.

For example, one luxury jewelry company uncovered billing errors that saved them millions each month. Having visibility into both quoted rates and final invoices is crucial - something many businesses don’t realize until they face quarterly reconciliations.

Another key metric is "Where Is My Order" (WISMO) inquiry rates. One apparel retailer reduced their support tickets by 50% by using unified tracking and automated updates. This metric is a direct reflection of how well your carriers communicate tracking information, which greatly impacts customer satisfaction.

These metrics lay the groundwork for making informed carrier comparisons.

Comparing Carrier Performance

Comparing carrier performance reveals clear differences in reliability. For instance, if Carrier X delivers on time 98% of the time while Carrier Y only manages 85%, you have solid evidence to shift volume or renegotiate contracts. This insight is especially valuable during peak seasons when capacity constraints test the reliability of your carrier partnerships.

"Seeing the performance of a carrier through the Shipments view has been great for validating reliability and getting a clear, data-driven picture of carrier performance." - Tynan Dutson, eCommerce Operations Manager, Al's Sporting Goods

During the 2024 peak season, businesses that used analytics to guide carrier selection achieved a 95.4% on-time delivery rate, even amidst widespread capacity challenges. Even better, 79.5% of their shipments arrived within 4 days using affordable Ground or Economy services, avoiding the need for costly expedited shipping. Comparing actual transit times against service level promises can help you avoid overpaying for unnecessary speed.

Analytics also shine a light on hidden costs. By comparing quoted rates to actual billed amounts, you can uncover surcharges for residential deliveries, address corrections, or dimensional weight adjustments that quietly eat into your margins. For example, if two-day shipments are consistently arriving overnight, you’re likely paying for premium services when standard ground shipping would suffice.

This kind of comparative data drives smarter, more proactive cost management.

Data-Driven Optimization

Once you’ve got a handle on metrics and carrier comparisons, advanced analytics pave the way for continuous improvement. For instance, you can set up automated alerts to flag when a carrier’s on-time rate dips below a certain threshold - say, 90% - so you can reroute shipments before customers are affected. Weekly spend dashboard reviews can catch billing discrepancies early, while monthly deep dives reveal long-term trends.

If analytics show that 95% of your "5-7 day" shipments actually arrive in 4 days, you can confidently adjust the delivery window shown at checkout. This not only improves conversion rates but does so without altering your shipping strategy. These optimizations rely on accurate data about actual performance, rather than just carrier promises.

With 93% of shippers planning to increase technology investments by 2026 to meet rising customer expectations, analytics tools are becoming essential. The focus is shifting from historical reporting to predictive modeling that can forecast delays and cost increases before they occur. Platforms like Navexa integrate real-time analytics into their fulfillment systems, giving businesses the visibility they need to make informed, data-driven decisions without juggling multiple reporting tools.

| Operational Question | Metric to Track | Actionable Outcome |

|---|---|---|

| Why did costs increase? | Spend Dashboard (Surcharges & Adjustments) | Audit surcharges; renegotiate high-cost lanes |

| Are we overusing premium services? | Service Level Mix | Adjust shipping rules or checkout promises |

| Which carrier is driving delays? | On-time vs. Late Delivery % | Shift volume to more reliable carriers |

| Are invoices accurate? | Rated vs. Invoiced Spend | Catch billing discrepancies early |

| Are we ready for peak demand? | Label Volume Trends | Forecast staffing needs accordingly |

Conclusion

Dynamic labeling has turned shipping into a powerful tool for businesses. By automating tasks like rate comparisons, address validation, and shipment routing, it eliminates manual processes and trims costs by 10–15%. These efficiencies lead to noticeable gains in order processing and shipping expenses.

The numbers back this up. Modern e-commerce platforms, as seen in industry-leading systems, deliver substantial savings compared to custom-built solutions. They provide access to carrier discounts as steep as 90% off standard rates while managing the technical challenges for you.

"Shipping is now a solved problem. We let [the API] handle what they're good at, so we're free to solve other problems that are unique to our customer base." - Chrissy Pearl, Director of E-commerce, Sweetwater Gear Exchange

With global e-commerce expected to surpass $8 trillion by 2026, the race to ship faster and cheaper will only get tougher. Platforms like Navexa simplify this challenge by combining multi-carrier rate shopping, smart box optimization, and real-time analytics into one seamless system. This means you can stay competitive without the hassle of building custom tools.

Take action now: integrate address validation, set up automated carrier rules, and use analytics to catch and resolve issues quickly. These steps add up to lower costs and happier customers who get their orders on time, every time.

FAQs

How does dynamic labeling enhance accuracy and minimize shipping mistakes?

Dynamic labeling simplifies the shipping process by automatically creating carrier-specific labels. These labels come complete with verified addresses, barcodes, and service details, cutting out the need for manual input and ensuring every label aligns perfectly with its order.

This automation not only reduces the risk of human error but also boosts accuracy, prevents shipping mistakes, and saves valuable time for fulfillment teams.

How does dynamic labeling help e-commerce businesses save on shipping costs?

Dynamic labeling offers e-commerce businesses a smarter way to save money by automating label creation and optimizing shipping rates in real time. By connecting to multi-carrier systems, it ensures that each shipment is matched with the most budget-friendly carrier, cutting shipping costs by an average of 10-15%.

On top of that, dynamic labeling reduces manual errors and simplifies operations. This means businesses can handle shipments more quickly without compromising accuracy. The result? Lower costs, smoother processes, and happier customers.

How does dynamic labeling simplify international shipping and ensure compliance?

Dynamic labeling takes the hassle out of international shipping by automatically generating carrier-specific labels packed with all the necessary details for customs and compliance. It gathers crucial information like sender and recipient addresses, package dimensions and weight (measured in inches and pounds), item descriptions, quantities, values in USD, and HS tariff codes. On top of that, it creates the required customs forms and country-specific barcodes to align with international shipping standards.

To navigate the ever-changing regulations across countries and carriers, dynamic labeling platforms verify data against up-to-date compliance rules. This includes validating address formats, identifying restricted items, and ensuring the appropriate customs forms are included. Navexa, for example, incorporates these compliance checks directly into its multi-carrier rate shopping process. The platform instantly generates compliant labels, attaches the right documentation, and updates orders with tracking numbers in real time. This level of automation helps minimize errors, speeds up cross-border shipping, and allows e-commerce businesses to meet global shipping requirements with ease.

Ready to optimize your fulfillment?

Start saving on shipping costs and streamline your operations with Navexa.