How Multi-Carrier Shipping Reduces Costs

Want to cut shipping costs by up to 20%? Multi-carrier shipping is a proven way to save money and improve delivery reliability. Instead of relying on one carrier, this approach uses multiple providers like UPS, FedEx, USPS, and regional carriers. A centralized platform evaluates factors like weight, dimensions, and destination to pick the most cost-effective option for every shipment.

Key Benefits:

- Save 5–20% on shipping costs through rate shopping.

- Avoid delays by rerouting to alternate carriers during disruptions.

- Optimize packaging to reduce dimensional weight fees by 20–40%.

- Automate tasks like label creation and tracking to save time and reduce errors.

Quick Overview:

- Analyze costs: Review shipping data to find inefficiencies and calculate your baseline cost per package.

- Choose a platform: Select a system with rate shopping, box optimization, and carrier integrations.

- Set up automation: Automate carrier selection, label creation, and tracking.

- Negotiate better rates: Use data to secure discounts and reduce surcharges.

Platforms like Navexa bring all these features together, helping businesses save 10–15% while simplifying operations. Whether you're shipping 50 or 500 packages daily, multi-carrier shipping can reduce costs and improve efficiency.

Multi-carrier Shipping Strategy and Rate Shopping (ft. Nate Skiver)

Step 1: Review Your Current Shipping Costs

Before diving into a multi-carrier strategy, take a close look at your current shipping expenses. For direct-to-consumer brands, shipping typically takes up 8–15% of total revenue, often outpacing marketing costs. For fast-growing e-commerce businesses, this number can skyrocket, with shipping and transportation consuming up to 70% of the total budget. Having a clear baseline is crucial to measure potential savings.

Begin by collecting at least 30–90 days of historical shipping data, though a full year is even better to account for seasonal fluctuations. Gather all carrier invoices and shipping records, then calculate your Blended Cost per Package by dividing your total shipping spend by the number of packages shipped. This figure will serve as your benchmark for evaluating future cost reductions.

"Shipping is the hidden profit killer in DTC operations. Most brands accept carrier rates as fixed costs, then watch 8–15% of revenue disappear into shipping charges they could reduce by 20–30% with strategic negotiation and optimization."

- Marc Wulfraat, President, MWPVL International

Once you’ve established your baseline, turn your attention to carrier contracts to identify potential inefficiencies.

Review Carrier Contracts and Shipping Data

Dig into your carrier contracts and billing statements to uncover errors and inconsistencies. Surprisingly, 15–25% of residential surcharges are incorrect, often due to carrier database mistakes. Identifying these discrepancies can lead to refunds and savings.

To get a clearer picture, create a table that outlines key cost elements such as base rates, fuel surcharges, residential fees, and DIM (dimensional) weight divisors. For carriers like UPS and FedEx, the DIM divisor is typically 139. This means billable weight is calculated as (Length × Width × Height) ÷ 139. If your packaging is too large for lightweight items, you could be overpaying by as much as 40%.

Find Your Main Cost Drivers

With your baseline data in hand, identify the primary factors driving your shipping costs. Fees like fuel surcharges, residential delivery, and address corrections can increase expenses by over 30%. For example, residential delivery usually adds $4–6 per package, while address correction fees can cost $15–20 each time.

Zone distribution is another key driver. Shipping to higher zones (6–8) significantly raises costs. Additionally, examine your service level mix. Many businesses rely too heavily on expensive Air services for zones where Ground shipping would suffice. Ground delivery is the most economical option (1.0x), while 2-Day Air costs about 2.8x more, and Next-Day Air can be 5.6x more expensive.

Between 2020 and 2023, shipping costs surged 35–50%, driven by fuel surcharges and carrier pricing power. By addressing these cost drivers, mid-sized brands can save anywhere from $30,000 to $150,000 annually. Understanding these factors is critical for negotiating better rates and optimizing your shipping strategy. With this knowledge, you’ll be better equipped to explore multi-carrier solutions effectively.

Step 2: Choose a Multi-Carrier Shipping Platform

Once you've analyzed your shipping costs, the next step is to pick a multi-carrier platform that simplifies rate comparisons and connects you with various carriers. Why does this matter? Because it can cut shipping costs by 5–20% and help tackle the 39% of cart abandonments caused by high shipping fees. Choosing the right platform isn’t just about saving money - it’s about creating a smoother, more efficient shipping process.

Features to Consider

When evaluating platforms, look for these key features:

- Real-time rate shopping: The platform should compare rates across national, regional, and local carriers instantly.

- Automated carrier selection: It should assign carriers based on factors like weight, zones, and delivery speed.

- Box optimization: A feature that minimizes chargeable weight by 20–40% through smarter packaging.

- System integrations: Compatibility with major e-commerce platforms, ERP systems, and warehouse management software.

- Performance dashboards: Access to detailed analytics for tracking and improving shipping operations.

How Navexa Fits the Bill

If you’re looking for a platform that checks all these boxes, Navexa is a strong contender. This all-in-one fulfillment platform can reduce shipping costs by 10–15% using automated rate comparisons and advanced box optimization. Navexa evaluates rates in real time across a variety of carriers - national, regional, and local - to find the best option based on price, speed, and destination.

Its box optimization feature is particularly useful, ensuring that orders are packed efficiently to avoid wasted space and unnecessary dimensional weight charges. Plus, with integrations across more than 50 platforms - including major marketplaces, ERP systems, and warehouse tools - Navexa automates tasks like order processing and label creation. This not only saves time but also reduces errors like incorrect address entries, which can be costly.

Navexa also centralizes tracking, giving customers better visibility into their deliveries while cutting down on customer service inquiries. And if your business ships 50–100+ packages daily, Navexa scales effortlessly during peak seasons, ensuring smooth operations without any hiccups. By combining rate shopping, smart packaging, and deep system integrations, Navexa helps businesses streamline their fulfillment processes and handle growth with ease.

Step 3: Connect and Set Up the Platform

Once you've chosen your multi-carrier platform, the next step is to integrate it with your e-commerce store, carrier accounts, and warehouse. This setup allows for automatic data flow, eliminating the need for manual entry and enabling automated shipping decisions. Most platforms come with pre-built connectors for popular e-commerce platforms like Shopify, Magento, BigCommerce, Amazon, and eBay. These connectors handle automatic order imports and real-time inventory updates seamlessly. For businesses with custom setups or high shipping volumes, RESTful APIs and SDKs can embed shipping logic directly into your existing tech stack.

The integration process usually involves linking your carrier accounts through a Bring Your Own Account (BYOA) system. This requires entering your carrier credentials or account object IDs into the platform. Before officially launching, use test API keys or sandbox environments to verify that order data, labels, and tracking numbers are processed correctly.

Configure Automation Rules

Once everything is connected, it's time to set up automation rules to streamline your shipping process. These rules can automatically choose carriers based on details like package weight, dimensions, destination, and delivery speed. Start by focusing on your busiest shipping routes - this approach delivers immediate savings and a noticeable impact.

You can also create Method Merging Rules, which group similar carrier services (like UPS Ground and FedEx Home Delivery) under a single checkout label, such as "Standard Shipping." This ensures customers always see the most cost-effective option. Accurate inventory data is critical here. Details like product weight, height, and width must be precise, as research shows that 22% of shipped packages could have been sent at a lower cost with better inventory management. Beyond setting up these rules, keeping your system accurate and up to date is essential.

Connect with Your Existing Systems

For smooth operations, ensure that your platform integrates seamlessly with your Warehouse Management System (WMS) and Enterprise Resource Planning (ERP) software. Real-time data synchronization and address validation are crucial to avoiding delivery mistakes. Platforms with strong integrations can save money and boost efficiency. For instance, shipping APIs with 99.99% uptime can handle thousands of shipments simultaneously, ensuring your business scales effectively - even during peak seasons.

Step 4: Set Up Rate Shopping and Optimization

Now that automation rules are in place, it’s time to activate rate shopping and box optimization. These tools work hand-in-hand to help you secure the lowest possible shipping costs while still meeting your delivery needs.

Compare Rates in Real Time

Rate shopping software is designed to instantly compare shipping rates across all your connected carriers. In just milliseconds, it pulls live rates through API integrations that account for fuel surcharges, zone-based pricing, and any applicable promotions. You can configure the system to prioritize specific parameters, such as cost, delivery speed, or overall value.

Start by creating rules for your most common shipping scenarios. For example, lightweight packages under 1 lb might be routed to USPS First-Class Package, which typically costs $4–$8. On the other hand, heavier shipments, like a 5 lb package going to Zone 5, might make more sense with UPS Ground, costing around $9–$12.

"What impressed me most... was their robust software, which also has all of the carrier's rates and carrier selection logic. For example, if we want to sell a certain bottle of wax, we can see which carrier can send it the cheapest." - John Lewis, President and COO of Vision Investments

The platform evaluates both your negotiated carrier rates (via BYOA) and any pre-negotiated discounts available through the platform. Whichever rate offers the better deal is automatically applied. This strategy can lead to transportation cost savings of 5% to 20%, depending on your shipping volume and the mix of destinations.

Once real-time rate comparisons are up and running, the next step is to focus on packaging efficiency to cut costs even further.

Apply Box Optimization

After comparing rates, box optimization ensures that each shipment is as cost-efficient as possible. This process, also called right-sizing, addresses one of the sneakiest shipping expenses: dimensional weight (DIM) charges. Most U.S. carriers calculate DIM weight using the formula (L×W×H) ÷ 139, charging based on whichever is greater - actual weight or dimensional weight. This means using an oversized box for a lightweight item could end up costing far more than necessary.

To combat this, input the exact dimensions of all your packaging options into the software. The system models various packaging configurations before creating the label, selecting the smallest box that safely fits the product. For instance, using a smaller container can significantly reduce the billable weight.

Keep a variety of box sizes in stock so the software has multiple options to choose from. Reducing filler material also helps keep package dimensions minimal. Navexa’s intelligent box optimization feature automates these calculations, ensuring you’re not overpaying for unused space. This approach typically results in a 10–15% reduction in shipping costs.

sbb-itb-ed0a9d1

Step 5: Automate Shipping Tasks and Tracking

Once you've got rate shopping and box optimization sorted, it's time to streamline your shipping process by automating label printing and tracking. This step not only reduces manual workload but also speeds things up significantly - some businesses have seen their processing times cut by more than half without needing to hire additional staff.

Automate Label Creation

Manual errors like typos or mislabeled packages can lead to costly headaches. By integrating APIs to pull order data directly, you can avoid these issues entirely. These systems also validate addresses against carrier databases, catching mistakes like missing apartment numbers or incorrect ZIP codes before labels are printed. This simple step can save you from unnecessary returns and surcharges.

With your automation rules in place - such as "Use USPS First-Class for packages under 1 lb" - the system will automatically select the best carrier and service level for each order. For higher volumes, batch processing is a game-changer, allowing you to generate hundreds of labels at once. This becomes especially critical during busy periods when adding temporary labor isn’t feasible.

Once you've nailed label creation, the next focus should be on real-time tracking to ensure everything runs smoothly.

Track Performance and Make Adjustments

Even after automating, keeping an eye on your shipping system’s performance is essential. Centralized tracking brings all your carrier data into one dashboard, making it easier to monitor shipments. Plus, automated customer notifications keep buyers updated on their order status, which can significantly cut down on those "Where's my order?" inquiries.

Real-time analytics provide insights into carrier performance, tracking metrics like on-time delivery rates and transit times. If a carrier repeatedly misses deadlines or if delays occur at your fulfillment center, you can adjust your routing rules to shift shipments to more reliable carriers. Reviewing these metrics weekly ensures you catch problems early and can make quick adjustments, especially during peak seasons. Tools like Navexa’s analytics dashboard give you a clear view of all carriers, helping you make smarter, cost-effective decisions.

Step 6: Measure Results and Negotiate Better Rates

Track Key Metrics

Once you've rolled out a multi-carrier shipping strategy, it's crucial to monitor key metrics to evaluate its performance. Start with your blended cost per package - a comprehensive metric that reveals whether your overall shipping expenses are increasing or decreasing.

Pay close attention to surcharges and accessorial fees, which can quietly inflate your costs by 30% or more. For service quality, track essential indicators such as on-time delivery rate (aim for 95% or better), damage rates (keep it under 0.5%), and lost package rates (target below 0.2%). To stay on top of these metrics, implement a routine: review delivery performance weekly, analyze cost trends monthly, and schedule quarterly business reviews with your carrier representatives. Tools like Navexa's analytics dashboard can simplify this process by consolidating data from all carriers, helping you spot trends and address issues before they hurt your bottom line.

These insights are not just for monitoring - they're the foundation for negotiating better terms with your carriers.

Use Data to Negotiate Better Contracts

Armed with your metrics, you can approach carrier negotiations with confidence. Focus on landed costs, which include all surcharges, rather than just the base rate per package. For instance, in 2025, iDrive Logistics helped a food and beverage company uncover excessive fuel surcharges through detailed shipping data analysis. By tweaking their carrier mix, the company managed to cut shipping costs by 16%.

When negotiating, aim for specific concessions that match your shipping profile instead of broad discounts. For example, if residential delivery fees make up a significant portion of your costs, negotiate a waiver or reduction for those charges. Use your data to back up requests, such as volume distribution by carrier, shipping zone, and service level. A notable example: ShipSigma worked with an e-commerce business spending $11 million annually on shipping. By analyzing invoices and renegotiating with their carrier, they secured $3.1 million in savings in just 41 days.

"The first rule to take into any carrier negotiation is there is no universal best rate or method, only the best methods for specific profiles."

- Kris Gösser, Shipium

If you're a smaller business, platforms like Navexa can give you access to pre-negotiated enterprise rates, sparing you the hassle of direct negotiations. Additionally, auditing your invoices weekly with automated tools can help you recover 2% to 5% of your total shipping spend by catching billing errors and duplicate charges. This recovered money can strengthen your position during annual contract reviews.

How Multi-Carrier Shipping Reduces Costs

Multi-Carrier Shipping Cost Reduction Methods and Expected Savings

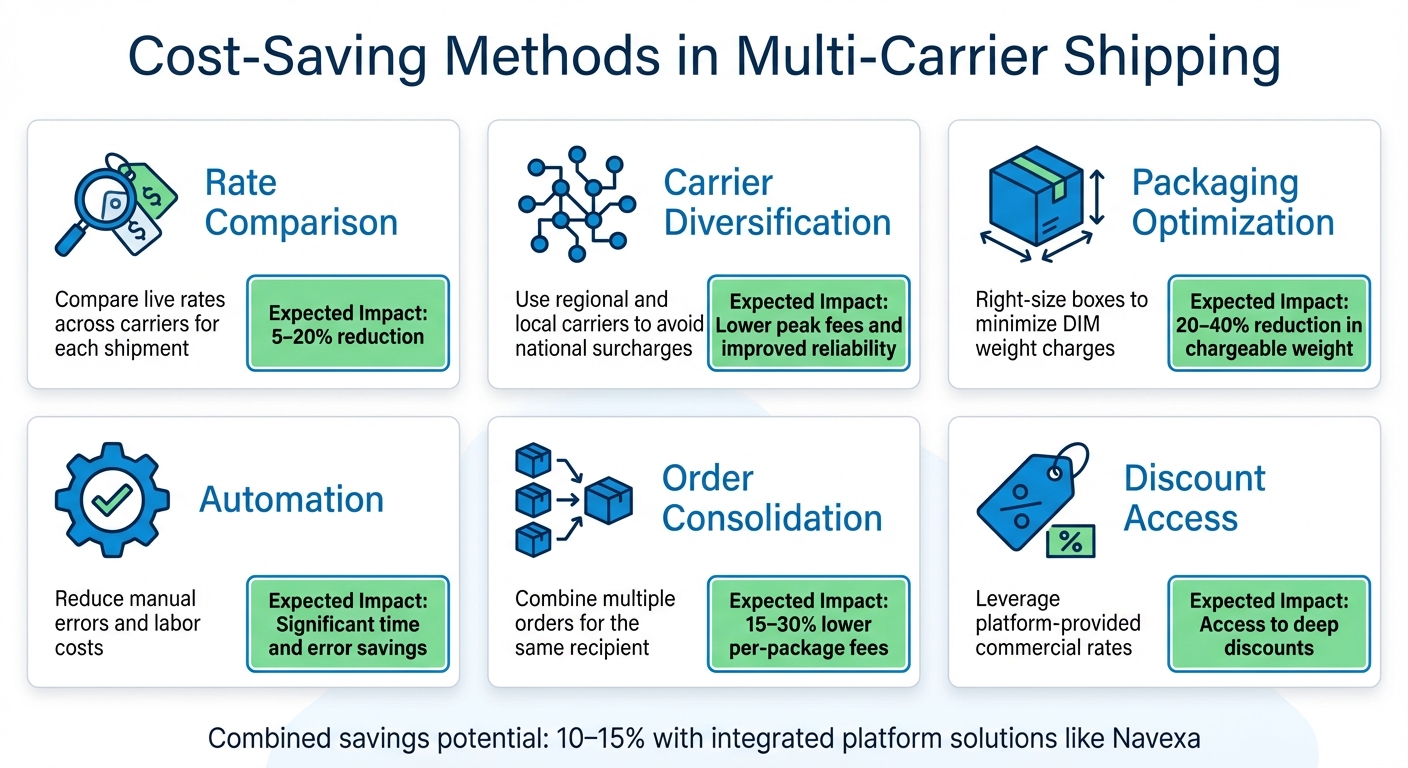

Multi-carrier shipping brings cost savings through a combination of six key strategies, each designed to address specific challenges in shipping logistics. Rate shopping is a standout method, automatically comparing live rates from national, regional, and local carriers for every shipment. By factoring in weight, dimensions, and destination, businesses can consistently select the most affordable shipping option. This approach often leads to notable reductions in overall shipping expenses.

Carrier diversification is another effective way to cut costs. By using a mix of carriers like UPS, FedEx, USPS, and regional options such as OnTrac, businesses avoid being overly dependent on a single carrier. This diversification helps sidestep peak-season fees, volume caps, and unexpected rate hikes. Additionally, automation streamlines processes, reducing manual errors and saving labor costs, while order consolidation - grouping multiple shipments to the same buyer or location - can slash per-package fees by 15–30%.

Packaging optimization plays a significant role in managing costs, particularly when it comes to dimensional (DIM) weight charges. By right-sizing boxes to fit the actual size of the product, businesses can reduce these charges by 20–40%. Furthermore, multi-carrier platforms often provide access to pre-negotiated commercial rates, offering small and medium-sized businesses discounts they wouldn't typically secure on their own.

Here’s a quick breakdown of these methods and their potential impact:

Cost-Saving Methods Comparison

| Method | Description | Expected Impact |

|---|---|---|

| Rate Comparison | Compare live rates across carriers for each shipment | 5–20% reduction |

| Carrier Diversification | Use regional and local carriers to avoid national surcharges | Lower peak fees and improved reliability |

| Packaging Optimization | Right-size boxes to minimize DIM weight charges | 20–40% reduction in chargeable weight |

| Automation | Reduce manual errors and labor costs | Significant time and error savings |

| Order Consolidation | Combine multiple orders for the same recipient | 15–30% lower per-package fees |

| Discount Access | Leverage platform-provided commercial rates | Access to deep discounts |

Navexa integrates all these methods into a single platform, enabling e-commerce businesses to cut shipping costs by 10–15% while simplifying their fulfillment processes. The real advantage lies in using these strategies together, as relying on just one or two won’t yield the same level of savings or efficiency.

Conclusion

Multi-carrier shipping isn’t just about saving money - it’s about creating a stronger, more adaptable fulfillment process. By cutting shipping costs by 5–20% and reducing the risk of disruptions, it also directly improves the customer experience.

With better delivery options, real-time tracking, and reliable on-time arrivals, customer satisfaction increases, which helps build long-term loyalty. This makes diversifying carriers a smart strategy rather than just an optional upgrade.

Navexa brings all these elements together in one platform, offering multi-carrier rate shopping, intelligent box optimization, and automated workflows to simplify operations and reduce shipping costs by 10–15%. Its real-time analytics provide the insights you need to monitor performance, uncover cost drivers, and make informed decisions to refine your fulfillment strategy.

To keep your six-step shipping strategy effective, regularly evaluate carrier performance and fine-tune your automation rules. Treat multi-carrier shipping as an ongoing process of improvement, not a one-and-done task. Use the shipping data at your disposal to negotiate better contracts and maintain competitive rates as your business grows. The key to staying ahead lies in continuous optimization.

Ready to take the next step? Start your 14-day free trial with Navexa and see how you can cut costs and improve your fulfillment process.

FAQs

How does using multiple carriers improve delivery reliability?

Using more than one carrier can make deliveries more reliable by offering flexibility and reducing reliance on just one shipping provider. It lets businesses pick the most suitable carrier for each shipment, considering factors like where it's going, how quickly it needs to arrive, and how well the carrier is performing at the moment.

By spreading shipments across multiple carriers, businesses can sidestep problems like weather-related delays, labor strikes, or capacity issues that might affect a single provider. Plus, comparing rates across carriers helps ensure you’re choosing the most affordable and dependable option for each delivery, which can lead to more consistent service and happier customers.

What should I consider when choosing a multi-carrier shipping platform?

When choosing a multi-carrier shipping platform, it's essential to focus on features that help cut costs, boost efficiency, and offer flexibility. One standout feature to consider is real-time rate shopping. This lets you instantly compare carrier rates, making it easier to choose the most budget-friendly option for every shipment, which can lead to noticeable savings.

Another crucial feature is automation. Automating tasks like selecting carriers, generating labels, and updating tracking information can save time and reduce manual errors. Platforms that integrate smoothly with e-commerce systems and provide tools like inventory management or intelligent box optimization can simplify your shipping process even further.

If your business handles international shipping, ensure the platform supports cross-border shipping, including tools for managing customs and duties. Additionally, having access to analytics and reporting tools can give you insights into shipping performance while helping you spot areas to reduce costs. By focusing on these features, you can streamline your logistics and improve delivery efficiency.

How can I use shipping data to get better rates from carriers?

To secure better shipping rates from carriers, start by diving into your shipping data. Break down your costs, shipping volumes, and trends to uncover where your money is going. Pay close attention to things like base rates, surcharges, and extra fees - these are often the areas where savings hide.

Once you have a clear picture, use that data to showcase your shipping volume, performance, and the factors driving your costs. This gives you a solid foundation to negotiate for discounts, lower fees, or improved terms. And don’t stop there - regularly reviewing your shipping metrics can help you stay competitive and spot fresh opportunities to save.

With a clear, data-backed strategy, you’ll be in a strong position to negotiate contracts that cut costs and make your shipping operations more efficient.

Ready to optimize your fulfillment?

Start saving on shipping costs and streamline your operations with Navexa.