Batch Order Processing: Benefits and Methods

Batch order processing is a warehouse strategy that groups multiple orders based on shared traits - like identical items or shipping carriers - into a single workflow. This method reduces travel time for pickers, improves accuracy, lowers labor costs, and speeds up fulfillment. The three main techniques are:

- Batch Picking: Collects items for multiple orders in one trip, ideal for fewer SKUs with high repetition.

- Wave Picking: Organizes orders into timed waves, aligning with carrier schedules for strict deadlines.

- Zone Picking: Assigns pickers to specific warehouse zones, minimizing movement in large facilities.

Each method addresses different operational needs, and choosing the right one depends on factors like order volume, warehouse size, and product diversity. Tools like Warehouse Management Systems (WMS) and mobile scanners play a key role in implementing these techniques efficiently.

Batch vs Zone Picking: Which Is Better for Your Warehouse?

Benefits of Batch Order Processing

Batch order processing reshapes warehouse workflows by cutting down on unnecessary movement, reducing mistakes, and trimming costs. It brings measurable improvements to fulfillment operations, making them faster and more efficient.

Less Travel Time and Improved Picking Efficiency

Did you know warehouse pickers can walk up to 10 miles a day when handling orders one by one? Considering that order picking makes up over 50% of all labor activities in a warehouse, this constant movement adds hidden costs. Batch processing changes the game by consolidating trips. Instead of returning to the same storage location multiple times in a shift, pickers gather items for several orders in one go. A Warehouse Management System (WMS) plays a key role here, using routing algorithms to chart the quickest path through the aisles, cutting down on unnecessary back-and-forth.

The impact is significant: batch picking can reduce worker travel time by up to 55% and boost pick rates by 40%. For instance, batching single-line orders for 1,000 orders reduced the number of picking trips from 100 to 85. Fewer trips also mean less congestion in the aisles, enabling smoother movement for the staff.

"Batch picking eliminates the need to repeatedly revisit the same picking location multiple times in a shift as they fulfill orders, cutting travel time significantly." – Abby Jenkins, Product Marketing Manager, NetSuite

This streamlined approach not only slashes travel time but also lays the groundwork for better accuracy.

Higher Order Accuracy and Fewer Mistakes

Switching between a variety of products throughout the day can be mentally draining, increasing the risk of errors. Batch processing addresses this by allowing pickers to focus on one SKU at a time across multiple orders, reducing the chances of grabbing the wrong item. WMS platforms equipped with mobile barcode scanners or wearable devices verify each pick in real time, ensuring the correct SKU and quantity are selected before moving on. Additionally, zone batching - where workers stick to specific sections of the warehouse - helps them become familiar with a smaller range of products and locations, further cutting down on mistakes.

"Because pickers stay focused on one SKU at a time, it can be easier to focus on what's in front of them, minimizing mental fatigue and increasing accuracy." – Abby Jenkins, Product Marketing Manager, NetSuite

This boost in accuracy also translates to reduced operating costs.

Lower Labor and Operating Costs

On average, warehouse workers spend about 80% of their shifts walking. This unproductive time drives up labor expenses. By grouping trips to the same storage locations, batch processing helps businesses manage higher order volumes with fewer workers. Consolidating trips not only reduces labor hours but also minimizes wear and tear on equipment like carts and forklifts, lowering overall operating costs. Additionally, batching similar orders optimizes the use of packing materials and reduces errors that could lead to costly returns or re-shipping.

Batch picking can lead to a 15% reduction in labor costs. These savings make batching an invaluable strategy for boosting productivity and handling peak demand without significantly increasing labor expenses.

Faster Order Fulfillment and Better Customer Experience

Cutting down on travel and errors naturally speeds up the entire fulfillment process. In e-commerce, speed is everything. When pickers complete multiple orders in one trip instead of making separate journeys for each, orders move more quickly from "received" to "shipped." This ensures customers get their purchases faster. During high-demand periods, grouping orders with identical SKUs or those destined for the same shipping carrier helps avoid end-of-day bottlenecks. Single-line orders, in particular, are highly efficient - the order is complete as soon as the item is picked. Faster fulfillment also narrows the window for mistakes, leading to fewer delays and more reliable deliveries.

Easy Scaling for High Order Volumes

Beyond immediate efficiency gains, batch processing makes scaling much easier. As order volumes grow, managing them with single-order picking becomes impractical. Batch processing steps in to handle the increased demand without requiring a proportional jump in staffing or equipment. By automatically grouping similar orders, operations can handle spikes during busy seasons seamlessly.

It also eases congestion by reducing the number of pickers moving through the aisles at the same time. The growing adoption of batch picking reflects its importance - usage increased from 29% in 2022 to 39% in 2023, a 10% rise in just one year. These advantages highlight why selecting the right batch processing method is crucial, as explored in the next section.

Batch Order Processing Methods

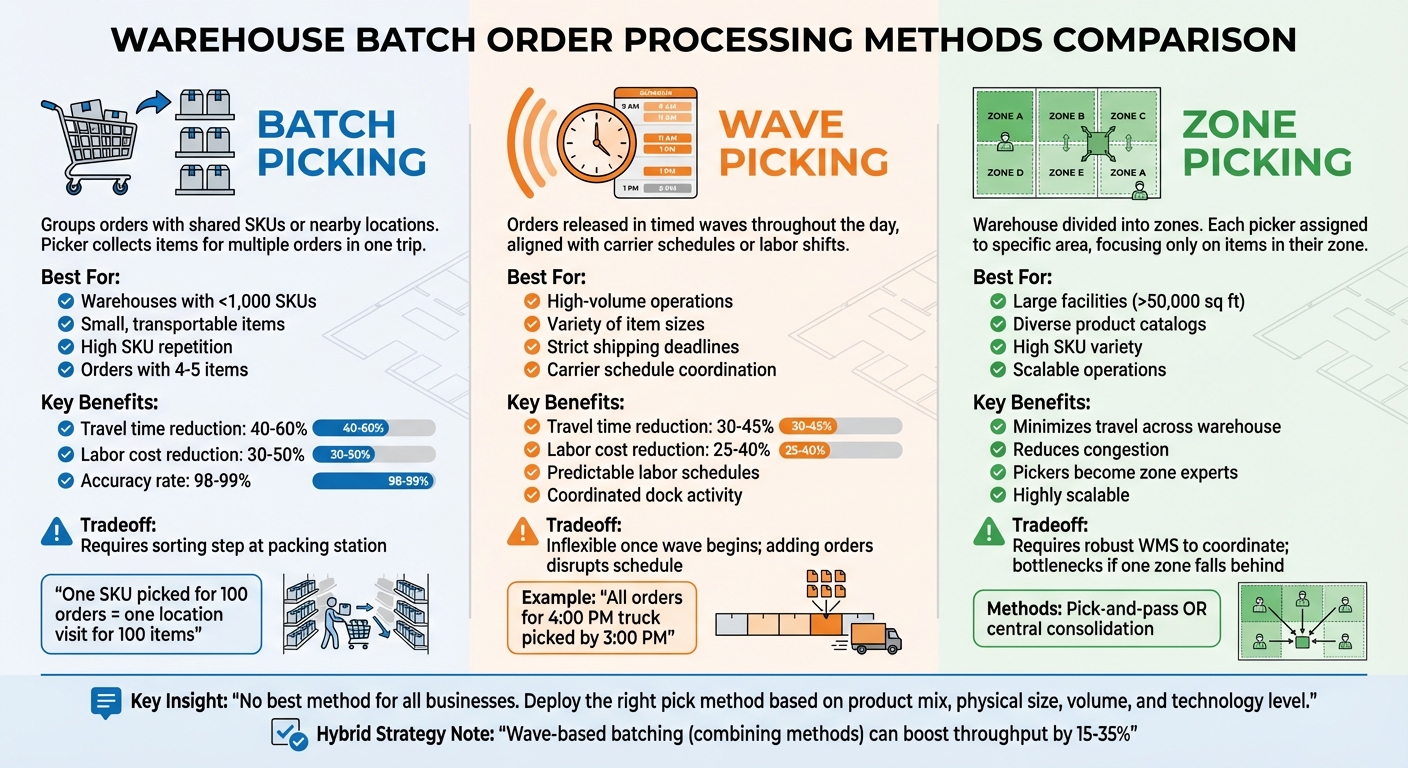

Batch Order Processing Methods Comparison: Batch vs Wave vs Zone Picking

Once you’re familiar with the benefits of batch processing, the next step is figuring out which method best suits your warehouse. The three primary methods - batch picking, wave picking, and zone picking - each offer distinct advantages depending on your operational needs. Here's a closer look at how each method works and the specific challenges they address.

Batch Picking

Batch picking groups orders with shared SKUs or nearby storage locations, allowing a picker to collect items for multiple orders in one trip. For instance, if 20 orders require the same product, the picker retrieves 20 units in a single visit and later sorts them into individual orders at a packing station.

This method is particularly effective in warehouses with small, easily transportable items and high SKU repetition, typically involving fewer than 1,000 SKUs. However, it does require an additional sorting step, which can lead to delays if not managed efficiently. To minimize errors, barcode validation is commonly used during the packing process. Batch picking can significantly reduce travel time by 40–60% and labor costs by 30–50% compared to single-order picking.

"It's a one-to-many relationship in terms of SKUs to orders. The benefit is heightened efficiency. If you have an instance where one SKU is picked for 100 orders, you go to the location one time and pick 100 items, which satisfies the requirement." – Rob Rickerson, Former Director of Operations and Analytics, Red Stag Fulfillment

Next, let’s examine a method centered around timing:

Wave Picking

Wave picking prioritizes time and scheduling over physical proximity. Orders are released in timed waves throughout the day, often aligned with carrier schedules or specific labor shifts. For example, orders for a 4:00 PM shipment are grouped to be picked by 3:00 PM. This approach works well for high-volume operations handling a variety of item sizes and operating under strict shipping deadlines [17, 20].

By creating predictable labor schedules and coordinating dock activity, wave picking ensures that orders are ready for carriers on time. It can reduce travel time by 30–45% and cut labor costs by 25–40%. However, the method can be inflexible - once a wave begins, adding last-minute orders can disrupt the entire schedule.

"Wave picking is the strategy of choice for high-volume operations... ensuring all orders for a 4:00 PM truck are picked by 3:00 PM." – Flex Logistique

Lastly, a method designed to localize tasks:

Zone Picking

Zone picking divides the warehouse into specific areas, with each picker assigned to a single zone. Pickers focus solely on items within their designated area, becoming highly efficient in their zone. Orders either pass through zones sequentially (pick-and-pass) or are consolidated at a central packing station. This method is ideal for large facilities with diverse product catalogs, where traveling across the entire warehouse would be impractical [17, 18].

By keeping pickers in fixed zones, this method reduces congestion and improves scalability as operations grow. However, it requires a robust Warehouse Management System (WMS) to coordinate tasks and avoid bottlenecks if one zone falls behind. Many warehouses now use hybrid strategies, such as wave-based batching, where orders are released by carrier deadlines and then sorted into batches within each zone.

"There is no best method for all businesses and there may be different picking methods within the same warehouse. You may have case picking at the order level and picking at the unit level in a cluster or pick-and-pass model." – David Haley, Director of Operations Consulting, Sharphurst LLC

Choosing the Right Batch Processing Method

Selecting the best batch processing method depends on factors like order volume, warehouse size, and the diversity of your product catalog. There's no universal solution - what works for a smaller operation may not suit a high-volume facility with tight deadlines.

Order volume is often the most critical factor. If you’re managing fewer than 100–200 orders daily, single-order picking might do the job. But once you surpass that range, methods like batch or wave picking become crucial for keeping labor costs in check. Considering that order picking makes up about 63% of total warehousing costs, choosing the right approach can significantly affect your profitability.

For setups with frequent SKU repetition, batch picking shines. On the other hand, wave or zone picking is better for mixed catalogs with items of varying sizes. In massive facilities with a wide range of SKUs, zone picking is particularly effective - it reduces unnecessary travel by restricting pickers to specific areas.

"One size does not fit all. You have to deploy the right pick method at the right time, both based on product mix, physical size, volume, and level of technology advancement." – Rob Rickerson, Former Director of Operations and Analytics, Red Stag Fulfillment

High-volume warehouses often adopt hybrid strategies to balance efficiency with tight schedules. For instance, wave-based batching - organizing orders into waves based on carrier cutoff times and then grouping them into multi-order batches - can boost throughput by 15–35%. This approach also retains the travel-reduction perks of batching. Ultimately, the goal is to align your picking method with your operational needs, rather than forcing a one-size-fits-all solution.

When to Use Batch Picking

Batch picking works best when dealing with orders that share common items, especially in catalogs with fewer than 1,000 SKUs. This method is particularly effective in environments where items are compact enough to be collected in carts or totes and where orders typically include around 4–5 items. However, there’s a tradeoff: after picking, items need to be sorted into individual orders at a packing station. Barcode validation during this sorting step helps maintain accuracy rates of 98–99%.

When to Use Wave Picking

Wave picking is ideal for operations with strict timing requirements and complex orders. It organizes work into scheduled blocks throughout the day, making it easier to plan shifts and coordinate dock activities. This method is especially suited for medium-to-high volume operations handling orders with multiple SKUs and varied item sizes. However, wave picking has its limitations. Once a wave starts, adding last-minute orders can disrupt the schedule, and uneven order flow may lead to downtime between waves.

When to Use Zone Picking

Zone picking is tailored for large warehouses (over 50,000 square feet) with diverse SKUs. By assigning pickers to specific zones, this method reduces travel time and boosts efficiency. It’s especially useful in facilities where extensive travel would otherwise slow down operations. However, coordinating zone picking can be challenging. Orders may need to move sequentially through zones (in a pick-and-pass system) or be consolidated at a central packing station. This process often requires a robust Warehouse Management System to ensure smooth execution. Zone picking leverages the efficiency and accuracy benefits discussed earlier, making it a strategic choice for large-scale operations.

sbb-itb-ed0a9d1

How to Implement Batch Order Processing

To truly capitalize on the benefits of batch order processing, the key lies in effective implementation. Transitioning from single-order picking to batch processing involves analyzing data, optimizing your warehouse layout, training your team, and leveraging the right technology.

Review Order Patterns and Warehouse Layout

Start by analyzing your order history to uncover patterns that make grouping orders into batches feasible. Look for trends like single-item orders, orders with the same SKUs, or those using the same shipping carrier. For instance, you could create batches for "single-item orders", "identical SKUs", or "same-carrier shipments".

Once you’ve identified these opportunities, focus on reorganizing your warehouse for efficiency. High-demand items should be placed in the "golden zone", which is within easy reach at waist height. Similarly, items frequently ordered together should be stored close to one another. To avoid bottlenecks, consider implementing one-way pick paths, especially if multiple pickers are working simultaneously. A warehouse management system can also calculate the shortest route to complete an entire batch in one trip.

Batch sizes should align with your physical constraints. For example, if your picking cart accommodates 12 bins, that’s your maximum batch size. Similarly, for pallet staging, calculate how many boxes fit on a single pallet. Separating single-line orders from multi-line ones can also streamline the process. Single-line orders can be completed as soon as the item is picked, significantly improving efficiency.

Train Staff on Batch Processing Methods

Your team plays a vital role in making batch processing work. Training should focus on familiarizing workers with mobile scanners, wearable devices, and your warehouse management system. The "verify" stage is especially important - this is where workers confirm SKUs and quantities using technology, as picking and sorting errors are among the most common warehouse issues.

Consider using simulation tools to help your staff practice batch processing before implementing it live. Role-playing exercises can also clarify procedures. Between 2022 and 2023, batch picking adoption grew from 29% to 39%, highlighting its growing importance. Tiered certification programs can encourage workers to develop their skills and master complex workflows. Regular feedback sessions are another valuable tool for identifying and resolving inefficiencies, such as adjusting batch sizes or refining picking routes.

Once your team is trained, technology can take batch processing to the next level.

Use Technology to Automate Batch Processing

Automation simplifies batch processing, transforming it from a manual task into a streamlined operation. A warehouse management system is essential here, as it uses logic-based rules to group orders by criteria like SKUs, volume, or shipping zones while keeping inventory data up-to-date in real time. For example, you can configure the system to automatically create batches for single-item orders, identical orders, or same-carrier shipments.

Set automated "Batch Cutoff Times" to align with your carrier pickup schedules, ensuring orders are processed on time. Controlled intake is another useful feature, as it prevents order flooding and maintains a steady workflow. Advanced systems even use algorithms to solve the "order batching problem", optimizing picker paths and batch groupings.

Digital picking lists replace traditional paper-based lists, allowing pickers to gather items for multiple orders in a single trip. Tools like wearable devices and SmartScan technology provide real-time instructions, optimized routes, and instant verification, minimizing errors. For example, in a warehouse processing 1,000 orders daily, separating single-line orders into dedicated batches reduced the total number of batches from 100 to 85, leading to a 15% boost in productivity.

"The ultimate goal is to create the batches in such a way that will eliminate as many steps as possible in the fulfillment process." – Geoff Greenhill, 3PL Software

How Navexa Improves Batch Processing

Navexa takes batch processing to a new level by tackling common challenges in order fulfillment. Its all-in-one platform helps cut shipping costs, boost inventory accuracy, and streamline repetitive workflows. Here's a closer look at the key features that make this possible.

Multi-Carrier Rate Shopping and Box Optimization

Navexa's multi-carrier rate shopping simplifies the packing process by grouping orders based on carrier or service level. This approach aligns order processing with carrier pickup schedules, reducing delays and labor costs. Automated rate selection ensures that the most cost-effective options are chosen every time.

The platform also excels in box optimization, selecting the most efficient packaging for each batch. This reduces material waste and lowers fulfillment expenses. Combined with strategic carrier selection, Navexa helps e-commerce brands cut shipping costs by 10–15% while also shortening transit times.

Inventory Forecasting and Real-Time Analytics

Navexa uses real-time analytics to refine order grouping and maintain accurate inventory data. This ensures pickers focus only on in-stock items, reducing errors like mis-picks and the need for re-picking. By analyzing patterns such as SKU proximity and order volume, Navexa creates batching rules that minimize travel time within the warehouse, saving both time and effort.

The platform's inventory forecasting aligns batch creation with carrier cutoff times and service level agreements, ensuring orders are processed at the right moment. Dynamic batching adapts to changes in order volumes, seasonal trends, and warehouse capacity, preventing bottlenecks. Real-time visibility into picker locations and order progress also helps manage congestion in busy areas of the warehouse.

Automated Workflows and Platform Integrations

Navexa streamlines operations by automating repetitive tasks, freeing up staff to focus on more important work. Its auto-batching groups orders based on predefined rules - like SKU, carrier, or warehouse - as soon as they come in, eliminating the need for manual intervention.

With integrations across over 50 platforms, Navexa ensures seamless syncing with ERP, CRM, and order management systems. This guarantees accurate data across all digital orders. Automated routing evaluates inventory levels and shipping costs to optimize batch fulfillment, while real-time analytics track key metrics like pick time, accuracy, and cycle duration. This automation trend aligns with industry data, where 69% of warehouse decision-makers are either using or planning to implement workflow automation by 2024.

Conclusion

Batch order processing offers a powerful way to cut labor costs, boost accuracy, and speed up fulfillment. Techniques like batch picking, wave picking, and zone picking tackle specific challenges, such as minimizing foot travel, handling peak demand, and avoiding warehouse congestion. Choosing the right batching approach is key to managing costs and meeting customer expectations effectively.

The push for automation has never been more pressing. With nearly 66% of global shoppers expecting delivery within 24 hours, faster and more efficient fulfillment is no longer optional - it’s essential.

To make the most of these advancements, integrating advanced technology is crucial. For instance, Navexa combines batching methods with cutting-edge tools to streamline operations. Features like automated order grouping, optimized pick paths, and multi-carrier integration help eliminate manual inefficiencies. Real-time analytics and inventory forecasting further reduce bottlenecks, while intelligent box optimization and rate shopping slash shipping costs by 10–15%. All of this ensures e-commerce brands can maintain the speed and precision today’s customers demand.

FAQs

How do I choose between batch, wave, and zone picking?

Choosing the right picking strategy - batch, wave, or zone - depends on your warehouse's order volume, product range, and operational goals.

- Batch picking is a great option for high-order volumes that share overlapping SKUs. It cuts down on travel time by allowing pickers to collect multiple orders in one trip.

- Wave picking prioritizes shipping deadlines. Orders are grouped into scheduled waves, ensuring they’re processed and shipped on time.

- Zone picking is well-suited for warehouses with a wide variety of SKUs. Pickers are assigned to specific zones, reducing congestion and streamlining the process.

Each method offers distinct advantages, so the choice should align with your warehouse’s specific needs.

What’s the best batch size for my warehouse carts and totes?

The best batch size for warehouse carts and totes varies depending on your specific operations, order volume, and the degree of product overlap. Typically, grouping orders with similar items can increase overlap and reduce travel time, which boosts efficiency. Tailor your batch size to these factors to streamline your workflow effectively.

What WMS and scanning tools do I need for batch processing?

For efficient batch processing, it's crucial to have a Warehouse Management System (WMS) equipped with barcode scanning and inventory tracking features. Combine this with handheld or mobile barcode scanners to minimize picking errors, improve accuracy, and keep inventory updates seamless. Look for tools that support real-time data synchronization and GS1-128 barcodes to enhance tracking and facilitate smooth data exchange, ultimately making operations more efficient.

Ready to optimize your fulfillment?

Start saving on shipping costs and streamline your operations with Navexa.